Quality Assurance Specialisation—Beyond Inspection to Strategy

Table of Contents

Quality Assurance: The Function That Determines Your Company's Reputation

Here’s a sobering truth: One defective product reaching a customer can destroy years of reputation building. One safety issue can shut down a facility. One regulatory violation can result in fines exceeding company annual profit.

Quality Assurance exists because these consequences are unacceptable.

While Quality Control focuses on inspection (checking if products meet standards), Quality Assurance is strategic—designing systems, processes, and practices that ensure quality is built in, not just checked in. QA is where quality becomes strategic business function rather than just operational task.

Quality Assurance specialists command some of the highest salaries in manufacturing because they directly prevent catastrophic problems and drive regulatory compliance.

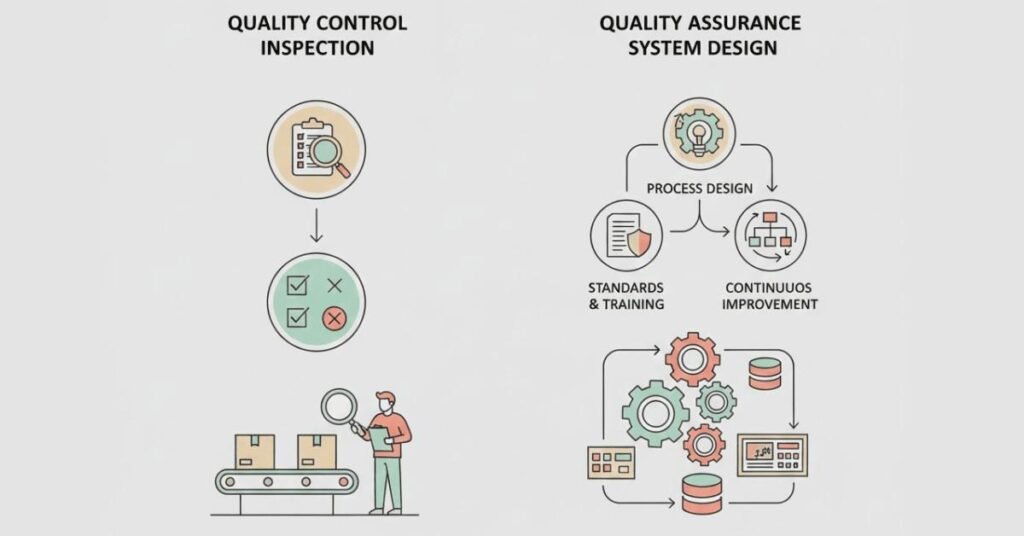

Understanding QA vs. QC (The Critical Distinction)

Quality Control (What We Discussed Before):

- Focuses on inspection and testing

- Detects defects after they occur

- Asks: “Is this product good or bad?”

- Reactive: Catches problems that escaped production

- Role: QC Inspector, QC Technician

Quality Assurance (What We’re Discussing Now):

- Focuses on prevention and system design

- Prevents defects from occurring

- Asks: “Why do defects occur? How do we stop them?”

- Proactive: Prevents problems before they start

- Role: QA Manager, QA Specialist, Quality System Manager

- Scope: Entire manufacturing system, suppliers, customers

Think of it like this:

- QC is a seatbelt (protects you after something goes wrong)

- QA is defensive driving lessons (prevents crashes from happening)

Better companies focus on QA: Prevent problems, not just catch them.

What Quality Assurance Specialists Actually Do

Sneha, Quality Assurance Manager at an Automotive Component Facility

Sneha manages the entire quality function for the facility (50+ employees, ₹100 crore annual business). Her day involves:

Monday: Supplier Quality Audit

A critical component supplier is showing increased defects in recent batches. Sneha:

- Reviews supplier data: Defect rate: 0.5% (was 0.1% previously)

- Conducts audit: Visits supplier facility, reviews their processes, interviews their operators

- Identifies root cause: Their raw material supplier changed; new material is slightly different

- Proposes solution: Work together to adjust their process for new material

- Implements corrective action: New process tested, validated, documented

- Tracks effectiveness: Monitors subsequent shipments—defect rate returns to 0.1%

Result: Supplier quality issue resolved. ₹20 lakh potential loss prevented (would have impacted our production).

Tuesday: Quality System Review

Annual internal audit to verify our quality management system meets ISO 9001 standards:

- Reviews procedures: Are documented procedures actually being followed?

- Interviews team: Asks operators, supervisors, engineers about quality practices

- Inspects records: Verifies quality documentation is complete and accurate

- Tests system: Runs sample through system, checks if processes work as documented

- Identifies gaps: Finds 3 areas where practice doesn’t match documentation

- Creates improvement plan: Documents findings, assigns responsibility, sets deadlines

Result: Documentation updated, training conducted, system strengthened.

Wednesday: Data Analysis & Trend Identification

Reviews last quarter’s quality data (500,000+ data points):

- Analyzes defect trends: Notices certain defect type increasing (delamination)

- Deep dives: Investigates production dates, equipment, operators, environmental conditions

- Identifies pattern: Delamination occurs on rainy days (humidity issue)

- Proposes solution: Improve humidity control in production area

- Calculates impact: Preventing this defect saves ₹50 lakh annually

- Prepares business case: Cost to fix: ₹10 lakh (HVAC upgrade), savings: ₹50 lakh = 3-month payback

Wednesday conclusion: Recommendation approved. Project initiated.

Thursday: Regulatory Compliance Review

Preparing for external ISO certification audit (happens annually):

- Reviews compliance: Are we following ISO 9001 requirements?

- Updates documentation: Ensures procedures reflect latest requirements

- Trains team: Briefs team on what auditors will check

- Prepares evidence: Gathers documentation proving compliance

- Conducts mock audit: Internal team plays role of auditor, identifies any gaps

- Fixes issues: Addresses any compliance gaps before external audit

Thursday conclusion: Team confident for external audit.

Friday: Strategic Planning & Management Review

- Prepares quality metrics: Monthly dashboard (defect rate, customer complaints, audit results)

- Reviews business impact: Quality costs vs. prevention benefits

- Plans initiatives: Next quarter: Implementing advanced inspection system using AI vision

- Participates in management review: Presents quality performance to leadership

- Discusses strategy: How quality function supports company growth plans

Result: New inspection system approved; budget allocated.

What This Shows:

Sneha’s role:

- Prevents defects (supplier audit prevented contamination issue)

- Ensures compliance (ISO standards maintained)

- Identifies systemic improvements (humidity control project will save millions)

- Manages strategy (quality systems support business growth)

- Drives continuous improvement (data analysis reveals improvement opportunities)

This is QA: Strategic, data-driven, preventive, and highly valuable.

Key Responsibilities of Quality Assurance Specialization

Quality System Development (25% of role):

- Design quality management systems

- Establish quality standards and procedures

- Create inspection plans

- Develop quality metrics and KPIs

- Ensure ISO compliance

- Document all quality processes

- Maintain quality manuals

Supplier Quality Management (20% of role):

- Evaluate and audit suppliers

- Establish supplier quality requirements

- Monitor supplier performance

- Implement supplier development programs

- Manage supplier issues and corrective actions

- Maintain supplier quality database

Process & Product Quality (20% of role):

- Conduct process capability studies

- Identify quality risks in processes

- Design quality control plans

- Implement process improvements

- Collaborate on product design (design for quality)

- Troubleshoot quality issues

Regulatory Compliance & Auditing (15% of role):

- Maintain ISO 9001, industry-specific certifications

- Prepare for external audits

- Conduct internal audits

- Maintain regulatory documentation

- Manage recalls and non-conformances

- Track regulatory changes

Data Analysis & Continuous Improvement (15% of role):

- Analyze quality data and trends

- Identify improvement opportunities

- Lead quality improvement projects

- Calculate quality costs and ROI

- Present quality metrics to management

- Implement Six Sigma/Lean projects

Team Leadership & Training (5% of role):

- Manage quality team

- Conduct quality training

- Develop quality culture

- Mentor junior quality staff

Conduct quality awareness program

Advanced Skills for QA Specialization

Quality Management Expertise:

- Deep ISO 9001 knowledge

- Statistical Process Control (SPC)

- Design of Experiments (DOE)

- Failure Mode & Effects Analysis (FMEA)

- Statistical analysis at advanced level

- Root cause analysis methodologies

Project Management:

- Lead complex quality projects

- Manage budgets and resources

- Timeline management

- Risk management

- Stakeholder coordination

Supply Chain Quality:

- Supplier evaluation and auditing

- Quality agreement development

- Supplier performance monitoring

- Quality cost analysis

Industry-Specific Compliance:

- Pharmaceutical: cGMP, validation, microbiology testing

- Automotive: IATF 16949, APQP, SPC

- Electronics: IPC standards, cleanliness requirements

- Medical Devices: FDA regulations, traceability

- Food: HACCP, food safety standards

Data & Analytics:

- Statistical software (Minitab, JMP)

- Data visualization and presentation

- Trend analysis

- Predictive quality modeling

ERP systems

Certifications That Drive QA Career Success

Six Sigma Black Belt (Most Valuable):

- Duration: 80-100 hours training

- Cost: ₹40,000-80,000

- Benefit: Salary increase ₹12,000-20,000/month, fast-track to management

- ROI: Highest among quality certifications

- Why: Black Belt proves capability to lead complex improvement projects

ISO 9001 Lead Auditor:

- Duration: 40 hours training

- Cost: ₹15,000-25,000

- Benefit: Enables auditing role, salary increase ₹5,000-10,000/month

- ROI: Essential for QA managers

Six Sigma Green Belt:

- Duration: 40-60 hours training

- Cost: ₹20,000-35,000

- Benefit: Salary increase ₹6,000-12,000/month

- ROI: Good starting point before Black Belt

APQP/PPAP (For Automotive):

- Duration: 30-40 hours training

- Cost: ₹12,000-20,000

- Benefit: Industry-specific expertise, salary bump ₹4,000-8,000/month

- ROI: High if targeting automotive sector

HACCP (For Food/Pharma):

- Duration: 20-30 hours training

- Cost: ₹10,000-18,000

- Benefit: Industry-specific expertise, required for many roles

- ROI: High if targeting pharma/food sector

Master of Business Administration (MBA – Operations/Quality):

- Duration: 2 years full-time or 3 years part-time

- Cost: ₹4,00,000-10,00,000

- Benefit: Salary increase ₹25,000-50,000/month, path to director roles

- ROI: Excellent if pursuing senior management

When: After 5+ years experience (you have context to apply MBA learning)

Special Certifications That Boost QC Career

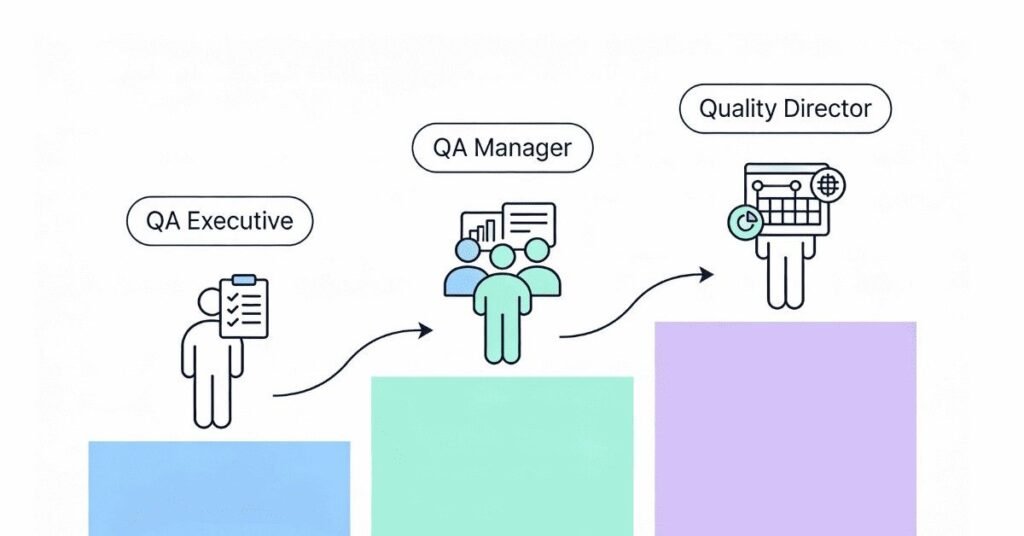

QA Executive / Quality Supervisor (Year 1-3):

₹32,000 – ₹48,000/month

(Transitioning from QC to strategic QA work)

QA Manager (Year 3-6):

₹48,000 – ₹75,000/month

(Manages quality function, strategic initiatives)

Senior QA Manager / Quality System Manager (Year 5-8):

₹70,000 – ₹1,15,000/month

(Department leadership, company-wide quality strategy)

Quality Director / VP Quality (Year 8+):

₹1,10,000 – ₹2,00,000+/month

(Executive leadership, board participation, strategic vision)

Salary Impact of Certifications:

- Black Belt: +₹12,000-20,000/month

- Green Belt: +₹6,000-12,000/month

- Lead Auditor: +₹5,000-10,000/month

- MBA: +₹25,000-50,000/month

Sector-Based Salary Variation:

Sector | QA Manager | Quality Director |

Pharmaceuticals | ₹55,000-80,000 | ₹1,25,000-1,80,000 |

Automotive | ₹50,000-75,000 | ₹1,15,000-1,65,000 |

Electronics | ₹52,000-78,000 | ₹1,20,000-1,75,000 |

Medical Devices | ₹55,000-82,000 | ₹1,30,000-1,90,000 |

Food Processing | ₹40,000-60,000 | ₹85,000-1,30,000 |

Pharma and medical devices pay highest for QA (regulatory complexity justifies premium salary).

Career Progression: QA Manager to Director

Year 1-2: QA Executive Transitioning to Strategy

- Salary: ₹32,000-48,000/month

- Role: Leading QA initiatives, data analysis, improvement projects

- Focus: Gain strategic perspective, develop project leadership

- Certification: Green Belt, ISO Lead Auditor

Year 3-5: QA Manager

- Salary: ₹48,000-75,000/month

- Role: Manage QA team, company-wide quality strategy, supplier quality, regulatory compliance

- Focus: Become strategic quality leader, build capability

- Certification: Black Belt, industry-specific certifications

Year 5-8: Senior Manager / Quality Director (Coordinator)

- Salary: ₹70,000-1,15,000/month

- Role: Lead quality function across departments, strategic planning, continuous improvement portfolio

- Focus: Enterprise quality leadership, business impact

- Certification: MBA or advanced specialization

Year 8+: Quality Director / VP Quality

- Salary: ₹1,10,000-2,00,000+/month

- Role: Executive leadership, board-level reporting, strategic vision, global responsibility

- Focus: Quality as competitive advantage, business growth driver

Why QA is Your Best Specialization If You're Strategic

Advantages:

- Highest salary ceiling: Directors command ₹1,50,000-2,00,000+/month

- Direct business impact: Quality improvements = cost savings = profit

- Strategic involvement: QA sits in board-level discussions, shapes company strategy

- Global opportunities: Quality expertise is universally valued; opportunities worldwide

- Recession-proof: Quality is never negotiable; functions protected during downturns

- Certifications with value: Black Belt, Lead Auditor certifications globally recognized

- Intellectual challenge: Complex problem-solving, strategic thinking

- Specialization value: Deep quality expertise is hard to replace, highly paid

When QA Might Not Be Ideal:

- If you prefer hands-on making over system design

- If you dislike detailed documentation and compliance

- If you’re uncomfortable with regulatory requirements

- If you dislike travel (audits require facility visits)

If you prefer technical solving over strategic thinking

How to Transition from QC to QA Specialization

Year 1-2 as QC Trainee/Executive:

- Master quality fundamentals

- Understand customer requirements

- Learn documentation and systems

- Build attention to detail reputation

Year 2-3: Strategic Shift to QA

- Request assignment to quality system projects

- Pursue Lean Green Belt certification

- Learn quality management system (ISO 9001)

- Participate in supplier audits

- Study advanced statistical methods

Year 3-4: QA Project Leadership

- Lead quality improvement projects

- Implement new quality procedures

- Coordinate supplier quality initiatives

- Pursue Six Sigma Black Belt

- Mentor QC team

Year 4-5: QA Manager Track

- Formal promotion to QA manager or senior QA executive

- Lead quality strategy for department/facility

- Manage supplier quality program

- Oversee internal audit function

The Bottom Line: QA is the Executive Career Path in Manufacturing

If you want the highest salary potential and executive-level responsibility in manufacturing, QA specialization is your path. The career trajectory is clear: QC Inspector → QA Executive → QA Manager → Quality Director.

India’s quality assurance specialty is expanding as companies recognize that prevention is cheaper than cure. Opportunities are abundant, salaries are premium, and the career is genuinely interesting.

Starting as a QC Trainee earning ₹15,000/month, following the QA specialization path with appropriate certifications, you can reach ₹1,50,000+/month as Quality Director within 10-12 years—a 10x salary increase—while gaining genuine executive influence and strategic responsibility.