Manufacturing Industry Career Guide: Your Complete Roadmap from Fresher to Professional

Table of Contents

PART 1: UNDERSTANDING THE MANUFACTURING INDUSTRY & WHY IT MATTERS FOR YOUR CAREER

What Exactly is Manufacturing, and Why Should You Care?

Think about everything around you right now—your phone, your laptop, even the chair you’re sitting on. Behind each of these items are factories, machines, engineers, and skilled workers. Manufacturing is the backbone of that entire process. It’s not just about creating products; it’s about solving real problems, improving efficiency, and building things that matter.

Here’s what makes manufacturing special compared to other industries: The work is tangible. You can literally see the impact of what you do. Manufacturing has evolved from the stereotype of loud, oil-stained warehouses into a sophisticated blend of hands-on craft and cutting-edge technology. Today, factories look more like tech labs, with robots, artificial intelligence, and data analytics driving production. This transformation means the industry now offers opportunities for people with diverse skill sets—whether you’re someone who loves working with machines, writing code, analyzing data, or managing operations.

Why does this matter for you as a fresher? The manufacturing sector is growing rapidly, especially in India. Hyderabad and Telangana have emerged as major manufacturing hubs, with companies investing heavily in sectors ranging from automobiles and electronics to pharmaceuticals and food processing. This means job opportunities are abundant, and salaries are competitive. More importantly, there are clear career pathways, training programs, and a strong demand for fresh talent.

The Modern Factory: Where Blue-Collar Meets White-Collar

A decade ago, manufacturing jobs meant choosing between being an operator on the factory floor or moving into management. Today, the lines are beautifully blurred. Modern factories employ automation engineers who program robots, data analysts who squeeze efficiency from production numbers, quality assurance specialists who use AI to spot defects, and sustainability officers who reduce waste. It’s a field where a mechanical engineer works alongside a software programmer, and a production supervisor collaborates with a data scientist—all on the same factory floor.

This shift happened because of Industry 4.0, also called the “Fourth Industrial Revolution.” It means factories aren’t just producing more; they’re producing smarter. Sensors on machines collect data every second. AI predicts when equipment might fail before it actually breaks. Workers use tablets and software to manage tasks that once required handwritten checklists. For freshers, this creates an exciting opportunity: you can enter manufacturing and immediately work with modern technologies. You’re not entering a “traditional” industry; you’re entering a transformed one.

Why Manufacturing Offers Job Security & Growth

Manufacturing is fundamental to any economy. Countries need to produce goods—whether it’s cars, medicines, electronics, or food products. Unlike trending startups that come and go, manufacturing remains stable and essential. Jobs in this sector range from entry-level positions starting around ₹10,000-15,000 per month to senior management roles exceeding ₹5,00,000+ annually.

Here’s the realistic picture for freshers: Entry-level manufacturing jobs are accessible with just a diploma or bachelor’s degree. You don’t need 5 years of experience to start. Companies actively hire freshers through trainee programs, graduate engineer trainee roles, and apprenticeships. Once you’re in, the growth trajectory is clear. A machine operator can become a shift supervisor, then a production manager. A quality control trainee can specialize and move into process engineering. The path is visible, and the steps are structured.

PART 2: MANUFACTURING CAREER ROLES—FROM ENTRY TO LEADERSHIP

The Three Levels of Manufacturing Careers

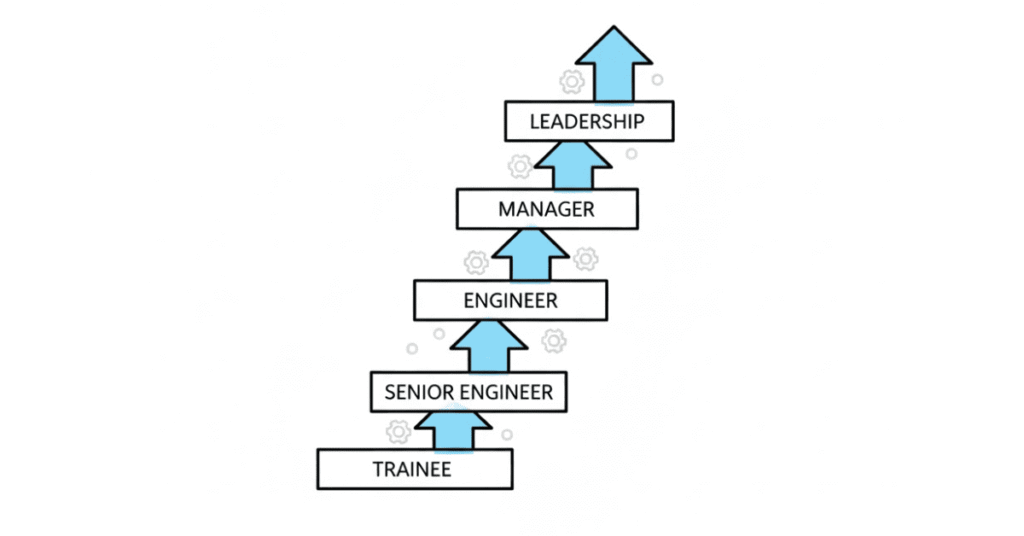

Think of manufacturing careers in three tiers: Foundation, Middle, and Leadership. Knowing where you want to be helps you pick the right starting point.

What Exactly is Manufacturing, and Why Should You Care?

These are positions where you’re learning the basics of manufacturing. Most of these roles don’t require prior experience, just willingness to learn and attention to detail.

Assembly Operator

What they do: Assemble components according to guidelines, ensuring products are built correctly. You follow blueprints, use hand tools or light machinery, and help maintain quality standards.

Why it matters: This is often a first step into manufacturing. You learn how products are assembled, understand quality standards, and get familiar with factory operations.

Expected salary: ₹8,000-15,000 per month (freshers)

Perfect if: You’re detail-oriented, enjoy hands-on work, and want to understand production basics.

Quality Control Trainee / Quality Checker

What they do: Inspect products to catch defects before they reach customers. You might use simple testing equipment, visual inspections, or computer-based quality systems.

Why it matters: Quality is everything in manufacturing. A single defective product can damage a company’s reputation or, in pharmaceuticals, put lives at risk. QC roles teach you precision and responsibility.

Expected salary: ₹10,000-20,000 per month (freshers)

Perfect if: You like attention to detail, have an eye for spotting problems, and understand that your work protects end customers.

Mechanical Fitter

What they do: Assist in assembling, fitting, and maintaining machinery. You might learn welding basics, understand how equipment is put together, and help with minor repairs.

Why it matters: This is a skilled trade that’s in high demand, especially with the rise of electric vehicles. Fitters are needed across industries.

Expected salary: ₹12,000-18,000 per month (with trade certification)

Perfect if: You have ITI training or a technical diploma and enjoy hands-on mechanical work.

Production Trainee

What they do: Work under supervision on the production floor, learning processes, safety procedures, and production standards.

Why it matters: This role is your orientation to manufacturing life. You’re building muscle memory, understanding workflows, and proving your reliability.

Expected salary: ₹10,000-16,000 per month

Perfect if: You’re fresh out of college and want structured learning before specializing.

TIER 2: MIDDLE-LEVEL ROLES (2-5 Years of Experience)

After gaining foundational experience, you can step into roles with more responsibility and technical depth.

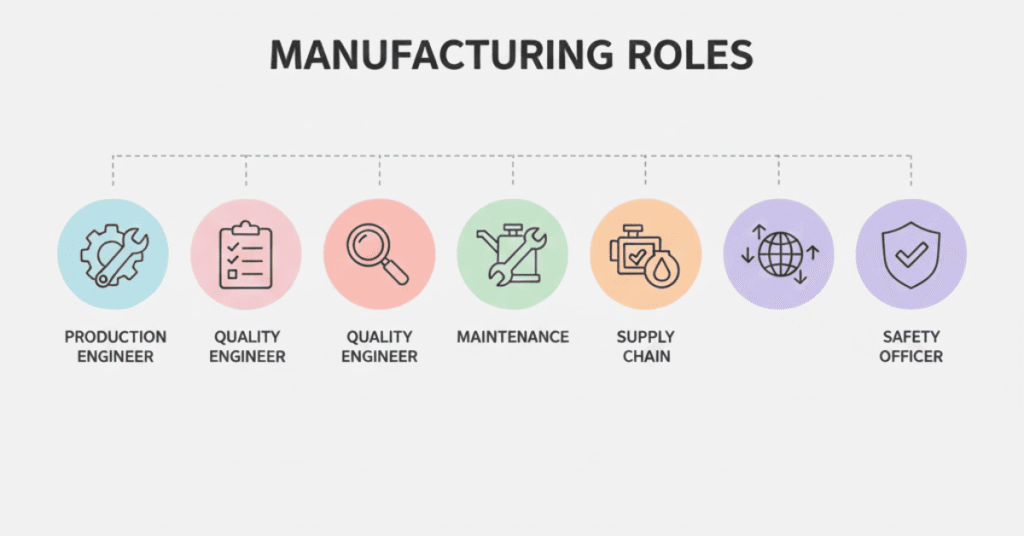

Production Engineer / Manufacturing Engineer

What they do: Analyze production processes, identify bottlenecks, and suggest improvements. You use CAD software to design solutions, work with teams to implement changes, and track efficiency metrics.

Key skills: CAD software (AutoCAD, SolidWorks, CATIA), process optimization, material science, lean manufacturing, statistical analysis

Expected salary: ₹3,00,000-5,00,000 annually

Why it’s valuable: You’re not just doing the work; you’re improving how work gets done. Companies love this.

Perfect if: You have engineering background and enjoy problem-solving.

Automation Technician / Robotics Technician

What they do: Install, maintain, and troubleshoot robots and automated systems. You monitor robot performance, fix issues, and ensure production lines run without glitches.

Why it matters: Automation is the future. Robots and AI systems need skilled humans to operate and maintain them.

Expected salary: ₹2,50,000-4,00,000 annually

Perfect if: You enjoy working with technology, like learning new equipment, and want to be on the cutting edge.

Quality Assurance Specialist

What they do: Beyond basic inspection, you develop quality standards, analyze defect trends, use statistical tools, and work on continuous improvement initiatives. In pharmaceuticals or food, you might conduct microbiological tests.

Expected salary: ₹2,50,000-3,50,000 annually

Perfect if: You want to move from simple QC to strategic quality management.

Logistics & Supply Chain Coordinator

What they do: Manage material flow, ensure timely procurement, coordinate inventory, and optimize distribution. You work across the entire supply chain—from suppliers to customers.

Expected salary: ₹2,00,000-3,00,000 annually

Perfect if: You enjoy planning, coordination, and seeing the bigger operational picture.

TIER 3: LEADERSHIP ROLES (5+ Years of Experience)

Production/Plant Manager

Oversees the entire factory operation. Manages budgets, staff, safety, production targets, and strategic improvements. Expected salary: ₹6,00,000-12,00,000 annually.

Maintenance Manager/Engineering Manager

Leads the maintenance and engineering teams, ensures equipment reliability, and drives technical innovation. Expected salary: ₹5,00,000-10,00,000 annually.

Quality Manager

Sets company-wide quality standards, manages QA teams, and ensures compliance with industry regulations. Expected salary: ₹5,00,000-9,00,000 annually.

PART 3: ESSENTIAL SKILLS YOU NEED TO SUCCEED IN MANUFACTURING

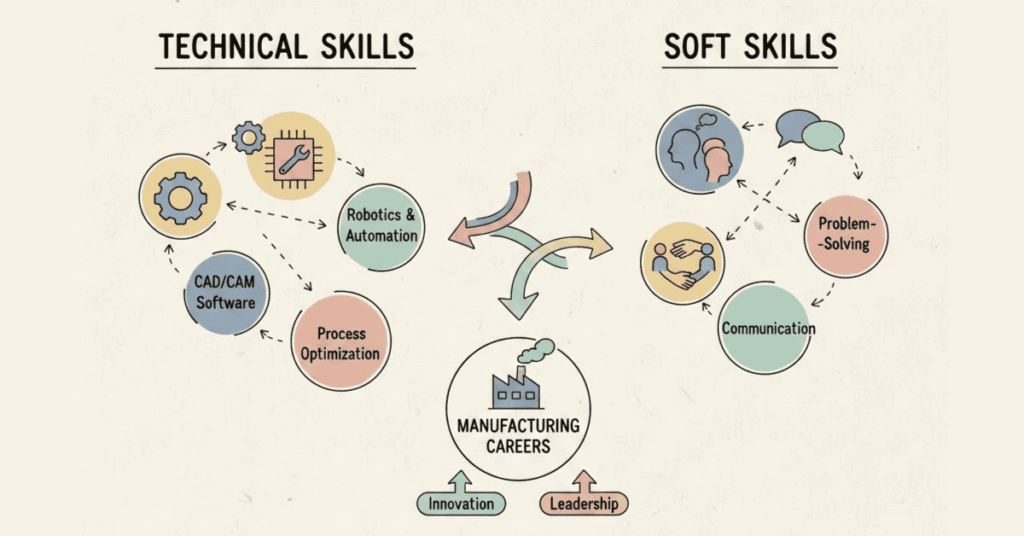

Manufacturing success isn’t just about technical knowledge. It’s a combination of hard skills (technical abilities) and soft skills (people and communication abilities).

Hard Skills (Technical)

- CAD Software & Technical Drawing

Why it matters: Manufacturing is precision-based. Engineers and technicians use CAD (Computer-Aided Design) to create accurate blueprints and 3D models.

Software to learn: AutoCAD, SolidWorks, CATIA

How to get started: Online courses available on Udemy, Coursera; many are free or very affordable

Time investment: 40-60 hours to get comfortable

Real-world example: A manufacturing engineer uses SolidWorks to design a modified assembly line, saving the company 10 hours of daily production time. - Lean Manufacturing & Process Optimization

What it means: Lean is a philosophy of eliminating waste and maximizing efficiency. It sounds simple, but it’s transformative.

Practical application: You identify why a process takes 2 hours when it could take 1.5 hours. You eliminate unnecessary steps.

How to learn: Free intro courses online, or pursue Lean Six Sigma certification (green belt or black belt)

Impact: Companies reward employees who save time and money through process improvements. - Quality Control & Statistical Analysis

Why critical: Quality issues directly impact customer satisfaction and safety. In pharmaceuticals, quality mistakes are life-threatening.

Skills involved: Data analysis, trend spotting, using quality management software, sometimes basic statistics

Tools to learn: Minitab, JMP, Excel-based analysis

Salary boost: QA specialists with statistical expertise earn 20-30% more than basic QC workers. - Material Science & Properties

Understanding: Different materials (steel, aluminum, plastics, composites) have different properties. Knowing when to use which material matters.

Application: A manufacturing engineer selects aluminum instead of steel for a car part to reduce weight while maintaining strength. Result: improved fuel efficiency. - Safety & Health Protocols (EHS)

Why mandatory: Every factory must follow safety regulations. Workers must understand hazard identification, proper equipment usage, and emergency procedures.

Certification: OSHA (Occupational Safety and Health Administration) basics; many companies provide this training.

Career angle: EHS Officers are increasingly in demand. It’s a specialized track with good salary prospects.

Tech-Forward Skills (For Modern Manufacturing)

PLC Programming & SCADA Systems

What it is: PLC (Programmable Logic Controller) systems control factory equipment. SCADA (Supervisory Control and Data Acquisition) systems monitor and manage production data.

Demand: High. Companies report that nearly 40% of large manufacturers use AI-powered systems.

Learning: Technical courses through institutes; some companies train on-the-job.

Data Analysis & AI in Manufacturing

Emerging role: 62% of manufacturing firms plan to hire digital transformation leads by next year.

Skills: Basic Python or R programming, understanding of machine learning concepts, data visualization

Real-world use: Predictive maintenance—sensors detect machinery wear before failure occurs, preventing costly downtime.

CNC Machine Operation

What it is: CNC (Computer Numerical Control) machines cut and shape materials with precision. Operating them requires technical knowledge and attention to detail.

Demand: Strong, especially in automotive and aerospace sectors.

Soft Skills (Every Job Needs These)

- Problem-Solving

Manufacturing constantly throws curveballs. Machine breaks unexpectedly. Material shipment is delayed. Production targets are tight. Your ability to stay calm and find solutions is invaluable.

Example: A production line malfunctions. While others panic, you systematically check each component, identify the issue in 20 minutes, and implement a fix. This saves the company hours of downtime. - Teamwork & Communication

Manufacturing is collaborative. You work with operators, engineers, supervisors, quality teams, and suppliers. Clear communication prevents mistakes and improves efficiency.

Soft skill angle: Able to explain technical issues to non-technical managers? Great. Can understand what a supervisor needs and deliver? Invaluable. - Safety Mindset

In manufacturing, safety is non-negotiable. One careless moment can cause injury. The best employees are those who never compromise on safety—for themselves or teammates. - Adaptability

Manufacturing changes. New equipment arrives. Processes are updated. Certifications evolve. Thriving here means staying curious and willing to learn continuously.

PART 4: HOW TO START YOUR MANUFACTURING CAREER (Your Roadmap)

What Qualifications Do You Need?

Here’s the honest answer: The manufacturing industry offers entry points for multiple qualification levels. You don’t necessarily need a four-year engineering degree to start earning and building a career.

Option 1: ITI (Industrial Training Institute) Diploma

Duration: 1-2 years

Trades available: Mechanical fitter, electrician, welder, CNC operator, toolmaker

Salary starting range: ₹10,000-18,000 per month

Advantages: Quick entry, hands-on training, immediate job placement

Best for: Those who want to start working quickly

Status in 2025: ITI qualifications are highly valued; government actively promotes ITI training through schemes.

Option 2: Polytechnic (Engineering Diploma)

Duration: 3 years

Specializations: Mechanical, Civil, Electrical, Production engineering

Salary starting range: ₹12,000-20,000 per month

Advantages: More comprehensive knowledge, opens doors to engineer-trainee roles

Best for: Those wanting technical depth plus management pathway

Option 3: Bachelor’s Degree (B.Tech/B.E.)

Duration: 4 years

Specializations: Mechanical, Production, Manufacturing, Industrial engineering

Salary starting range: ₹18,000-30,000 per month

Advantages: Fastest path to supervisory roles, best salary growth

Best for: Those planning long-term career in manufacturing

Option 4: Apprenticeship Programs (After Any Qualification)

Duration: 6-24 months (while working)

Structure: Company-sponsored, on-the-job training with salary

Unique advantage: You earn while learning

Government support: Programs like National Apprenticeship Training Scheme (NATS), Skill India Mission (PMKVY), and Dual System of Training (DST) are actively supported by the government with placement assistance.

Step-by-Step: Your First Year in Manufacturing

Month 1-2: Get Certified & Learn Safety

- Complete basic safety training (usually 1-2 days)

- Learn your company’s specific procedures

- Understand the factory layout and equipment

- Meet your supervisor and team

- First assignment: Observe, ask questions, and absorb the culture

Month 3-6: Master Your Role

- If you’re in QC: Learn inspection procedures, quality standards, and documentation

- If you’re an operator: Become proficient on your assigned machine

- If you’re in maintenance: Learn basic troubleshooting and equipment handling

- Key milestone: Working independently with minimal supervision

Month 7-12: Build Relationships & Learn Strategic Thinking

- Network with other departments—understand how production, quality, logistics, and engineering collaborate

- Identify where improvements can be made

- Take on small projects or responsibilities

- Key milestone: Recognized as reliable and valuable by your team

End of Year 1: Reflect & Plan Forward

- Ask for feedback on your performance

- Identify which aspects of manufacturing excite you most

Plan your next step: specialization, certification, or role advancemen

PART 5: SALARY, GROWTH & EARNING POTENTIAL

Realistic Salary Progression

Here’s a transparent breakdown of manufacturing salaries in India (specifically relevant for Telangana & Andhra Pradesh regions):

Entry Level (Fresher, 0-1 year):

- QC Trainee: ₹10,000-15,000/month

- Assembly Operator: ₹8,000-12,000/month

- Production Trainee: ₹10,000-16,000/month

- Graduate Engineer Trainee: ₹18,000-25,000/month

- Average annual: ₹1,20,000 – ₹3,00,000

Early Career (1-3 years):

- Junior QA Executive: ₹18,000-25,000/month

- Senior Operator/Shift Supervisor: ₹20,000-30,000/month

- Junior Production Engineer: ₹22,000-35,000/month

- Average annual: ₹2,50,000 – ₹4,50,000

Mid-Career (3-7 years):

- Production Engineer: ₹35,000-50,000/month

- Quality Manager: ₹40,000-60,000/month

- Maintenance Engineer: ₹35,000-55,000/month

- Average annual: ₹4,50,000 – ₹7,20,000

Senior Career (7+ years):

- Plant Manager: ₹50,000-1,00,000/month

- Engineering Manager: ₹50,000-90,000/month

- Operations Director: ₹60,000-1,20,000+/month

Average annual: ₹7,20,000 – ₹15,00,000+

The Real Growth Story

Manufacturing salaries grow based on two factors:

- Experience & Responsibility: More years = higher positions = better pay

- Specialization: Expertise in high-demand skills (automation, data analysis, quality systems) commands premium salaries

Manufacturing salaries in specialized roles or senior positions can exceed £100,000 annually (roughly ₹10,00,000+), especially for those in engineering, management, or digitalization roles.

Bonus & Incentive Structure (A Hidden Benefit Many Don't Know About)

Most manufacturing companies offer:

- Performance bonuses: Ranging from 20-50% of base salary based on production targets and quality metrics

- Shift allowances: Extra pay for working nights or weekends (10-30% additional)

- Incentives for improvement: Employees whose ideas save costs get rewards or bonuses

- Attendance bonuses: Regular bonuses for consistent presence

Example: A production engineer earning ₹40,000/month might actually take home ₹50,000-52,000/month with bonuses and allowances.

PART 6: GOVERNMENT SUPPORT & TRAINING PROGRAMS (Your Advantages as a Fresher)

The Government of India actively supports manufacturing training because the country needs skilled workers. Multiple schemes exist to help freshers enter manufacturing careers.

National Apprenticeship Training Scheme (NATS)

Who it’s for: Diploma and engineering graduates who want industry experience

Duration: 6-24 months, depending on the program

Support: Stipend/salary while training, job placement assistance

Benefit: Direct experience in real manufacturing environments

Pradhan Mantri Kaushal Vikas Yojana (PMKVY)

What it does: Provides short-term skill training aligned with industry needs

Sectors covered: Manufacturing, construction, automotive, electronics, and more

Cost: Usually free or heavily subsidized

Benefit: Industry-recognized certification + placement support

How to access: Check or visit your nearest skill center

Dual System of Training (DST)

Structure: Combines classroom learning at Industrial Training Institutes (ITIs) with hands-on industry training

Benefits: Comprehensive knowledge + practical experience

Outcome: Significantly improves job placement rates

Deen Dayal Upadhyaya Grameen Kaushalya Yojana (DDU-GKY)

Who it’s for: Rural youth seeking skill development

Support: Training + employment placement + monthly stipend

Benefit: Bridges the gap between rural and urban employment opportunities

MSME Skill Training and Employment Scheme

Focus: Small and Medium Enterprises (MSMEs)

Benefit: On-the-job training within actual manufacturing units

Advantage: Real work experience with guaranteed learning

Telangana-Specific Support

Since you’re targeting Telangana & Andhra Pradesh students, note that both states actively promote manufacturing as an economic growth area. Telangana has specific initiatives for engineering and capital goods manufacturing, creating demand for trained workers across multiple sectors.

PART 7: REAL SUCCESS STORIES & PRACTICAL TIPS

From Fresher to Production Engineer in 3 Years

Rajesh’s Story:

Rajesh completed his polytechnic diploma in mechanical engineering in 2022. He joined a pharmaceutical manufacturing company as a Production Trainee earning ₹14,000/month. For the first six months, he worked shifts, learning equipment and quality procedures. He noticed that a certain assembly process was taking unnecessarily long and suggested improvements to his supervisor. His supervisor took the idea forward, and it saved 2 hours daily.

By year 2, Rajesh became a Junior Production Engineer (₹28,000/month). He pursued online Lean Six Sigma training in his free time. In year 3, he became a Production Engineer (₹42,000/month) and now leads a team of operators. His approach: Learn the basics deeply, show initiative, and continuously improve.

Lesson: Growth in manufacturing rewards those who contribute ideas, not just follow instructions.

From QC Trainee to Quality Manager in 5 Years

Priya’s Story:

Priya started as a Quality Control Trainee in a food processing unit, earning ₹12,000/month. Her job was to inspect packaged products and flag defects. After 6 months, she noticed patterns in defects—certain products consistently had issues on specific production lines. She documented this and presented it to the QA manager.

Impressed, the manager encouraged her to pursue certification in quality systems (ISO 9001). Within 2 years, she became QA Executive. She then moved into quality planning and system development. After 5 years, she’s now a Quality Manager overseeing multiple departments, earning ₹55,000/month.

Lesson: In manufacturing, analytical minds who see patterns and suggest data-backed solutions rise quickly.

PART 8: LANDING YOUR MANUFACTURING JOB & ACCELERATING YOUR CAREER

Your Manufacturing Resume: Stand Out From Other Freshers

Most fresher resumes look identical. They list education, maybe a project or two, and that’s it. In manufacturing, recruiters want to see relevant skills, awareness of industry demands, and practical orientation. Here’s how to build a resume that gets noticed.

The Manufacturing-Optimized Resume Structure

Section 1: Header (Your First Impression)

What NOT to do:

text

RESUME

Rajesh Kumar

Phone: 99999XXXXX

Email: rajeshk99@gmail.com

What TO do:

text

RAJESH KUMAR

Production Engineering | Lean Manufacturing | Quality Systems

Phone: 99999XXXXX | Email: rajesh.kumar99@gmail.com | LinkedIn: linkedin.com/in/rajesh-kumar-prod

Location: Hyderabad, Telangana (Open to relocate within TP/AP)

Why the difference? Your header should immediately tell a recruiter which manufacturing role you’re targeting. Recruiters spend 6-7 seconds on a resume before deciding whether to read more.

Section 2: Professional Summary (2-3 Lines)

Instead of generic statements, write something specific:

Weak:

“Hardworking individual seeking opportunities in manufacturing.”

Strong:

“Production and Quality-focused engineering graduate with hands-on experience in process optimization, quality standards, and lean principles. Seeking Production Engineer or Quality Assurance role to contribute to operational excellence and continuous improvement initiatives in manufacturing environments.”

Section 3: Education (List Relevant Certifications)

text

Bachelor of Engineering, Mechanical Engineering

[College Name], Telangana | 2023-2024 (Expected)

Relevant Coursework: Production Engineering, Quality Management, Material Science, Manufacturing Processes

GPA: 7.2/10 (if above 7.0, include it; otherwise, skip)

Additional Certifications:

– Lean Six Sigma White Belt (Coursera, 2024)

– OSHA 30-Hour Safety Training (2024)

– ISO 9001:2015 Quality Management Basics (Online, 2024)

– CAD Fundamentals – AutoCAD (2024)

Why list certifications separately? Manufacturing values specific technical qualifications. Even free online certifications show initiative and learning mindset.

Section 4: Technical Skills (Be Specific)

Weak:

“Technical skills: MS Office, Communication, Problem-solving”

Strong:

text

Technical Skills:

– Software & Tools: AutoCAD, Excel (Data Analysis & Pivot Tables), Google Analytics, Canva

– Manufacturing Knowledge: Lean Six Sigma, Quality Control processes, ISO 9001 standards, Production planning

– Equipment Familiarity: CNC machines (basic understanding), Production line operations

– Systems: ERP systems (SAP basics), Manufacturing execution systems (MES)

Real talk: If you’ve never used CAD, don’t claim expertise. Instead, write “CAD Basics – AutoCAD (Self-taught through Udemy).” Honesty is respected; lies get caught during interviews.

Section 5: Experience / Projects (Make Them Manufacturing-Relevant)

As a fresher, you might not have formal work experience. That’s okay. Highlight projects, internships, and practical learning:

Example 1: Internship

text

Internship: Production Trainee

[Manufacturing Company Name], Hyderabad | Jan 2024 – Mar 2024 (3 months)

– Assisted in daily production planning for 3 assembly lines, ensuring 95%+ on-time delivery

– Identified and documented 5 process inefficiencies; one suggestion saved 90 minutes daily (4% efficiency gain)

– Maintained quality documentation and participated in daily quality audits

– Collaborated with shift supervisors and maintenance team to resolve production bottlenecks

Example 2: College Project

text

Project: Factory Layout Optimization (College Capstone)

– Analyzed existing production floor layout and material flow using Lean principles

– Designed optimized layout reducing material movement by 35%, completed in AutoCAD

– Presented findings to manufacturing experts; feedback incorporated into campus lab redesign

– Key Learning: Process mapping, data-driven decision making, stakeholder communication

Example 3: Certification/Skill Development

text

Lean Six Sigma Training & Certification

– Completed 40-hour Lean Six Sigma White Belt course

– Applied learning by analyzing a college canteen process, identified waste, and proposed improvements

– Certification obtained with score: 92/100

The manufacturing resume magic: Even if your projects are small, frame them in manufacturing language. Show that you understand efficiency, quality, safety, and continuous improvement.

LinkedIn Profile Optimization for Manufacturing Roles

Your LinkedIn profile is now your first impression. Many recruiters find candidates through LinkedIn before even asking for resumes. Here’s how to make it manufacturing-ready:

- Headline (Don’t Just Repeat Your Job Title)

Weak:

“Engineering Graduate | Seeking Manufacturing Role”

Optimized:

“Production Engineering Graduate | Lean Six Sigma White Belt | Quality & Process Optimization | Manufacturing Entry-Level Opportunities in Hyderabad, Telangana”

- About Section (Your Professional Story in 4-5 Lines)

text

“I’m an engineering graduate passionate about manufacturing excellence and operational efficiency.

During my internship at [Company Name], I worked across production lines and quality assurance, where I identified process inefficiencies and contributed ideas that increased efficiency by 4%. I’m particularly interested in:

– Lean Manufacturing & Process Optimization

– Quality Management Systems

– Manufacturing Technology & Automation

– Continuous Improvement Initiatives

I’m actively seeking Production Engineer, Quality Assurance, or Manufacturing roles where I can contribute to operational excellence while growing technically and professionally.

Currently exploring: Advanced manufacturing techniques, Industry 4.0 applications, and data-driven decision making in factories.

Let’s connect if you’re in manufacturing, recruiting, or exploring manufacturing careers!”

Why this works? You’re telling a story. You’re showing specific interest areas. You’re making it easy for recruiters to understand if you’re a match.

- Experience Section (Add Everything Relevant)

- Internships (even if 1-2 months)

- Relevant projects (college or personal)

- Volunteering or leadership in technical clubs

- Certifications and training completed

- Skills Section (Prioritize Manufacturing Skills)

Add skills and ask colleagues to endorse them:

- Lean Manufacturing

- Quality Control / Quality Assurance

- Production Planning

- Process Improvement

- CAD / AutoCAD

- ERP Systems

- OSHA Safety Standards

- Problem-solving

- Team Collaboration

- Recommendations (Critical for Freshers)

Reach out to your internship supervisor, college professors, or project mentors and ask them for a LinkedIn recommendation. Something like:

“Hi [Name], I’m building my professional LinkedIn profile as I start my manufacturing career. Would you mind writing a brief recommendation about my work during my internship? It would really help me connect with recruiters and companies in the manufacturing sector. Thank you!”

Even 2-3 recommendations from college professors or internship supervisors significantly boost your credibility.

Landing the Interview: Manufacturing Recruitment Process

Manufacturing hiring typically follows this path:

- Application screening (Your resume/LinkedIn gets reviewed)

- Technical test or aptitude test (Some companies test basic manufacturing knowledge)

- Phone/video screening call (HR rounds to confirm basics and interest)

- In-person technical interview (Usually with an engineer or production manager)

- Final interview (With department head or HR manager)

- Offer & joining formalities

Timeline: Fresher recruitment happens typically during:

- January-March (Post-college hiring)

- June-August (Mid-year hiring)

- September-October (Festive season hiring before year-end)

The best time to apply? As soon as you know you’re graduating or available. Companies often hire freshers in batches, and early applications get priority.

Where to apply:

- LinkedIn Jobs (search “Manufacturing Fresher” in Hyderabad, Telangana)

- Indeed India (Manufacturing roles, your city)

- Company careers websites (Visit Larsen & Toubro, Siemens India, Bosch, Mahindra, and other major manufacturers’ careers pages)

- Placement cells at your college

Recruitment agencies specializing in manufacturing

Common Manufacturing Interview Questions & How to Answer Them

Manufacturing interviews test both your technical knowledge and your practical mindset. Here are questions you’re likely to face:

Q1: "Walk us through the manufacturing process you're most familiar with."

Why they ask: They want to see if you understand production flow, not just theory.

Weak answer:

“Uh, it’s when raw materials become finished products?”

Strong answer:

“During my internship at [Company], I worked on the assembly line for [Product]. The process involved:

- Material Preparation: Raw materials (aluminum sheets, electronic components) are inspected and stored in designated areas

- Cutting/Shaping: Materials are cut using CNC machines to exact specifications from technical drawings

- Assembly: Components are assembled according to work instructions. For example, we assembled 120 units daily, ensuring each met quality standards

- Quality Check: Each unit undergoes 5-point inspection (dimensional accuracy, surface finish, functional testing, packaging standard, documentation)

- Packaging & Dispatch: Approved units are packed and shipped to customers

Throughout this process, I noticed that the transition between assembly and quality check involved unnecessary waiting—completed units sat for 30 minutes before inspection. I suggested we implement staggered inspection timing, which reduced waiting time by 40%.

The key insight I learned: Manufacturing is about moving things efficiently while maintaining quality. Every pause, every delay, every rework costs money.”

Why this works? You show:

- Process understanding

- Real experience

- Problem-solving mindset

- Awareness of efficiency

Q2: "How would you handle a situation where you found a defect in a product at the final stage?"

Why they ask: Safety and responsibility matter enormously in manufacturing.

Strong answer:

“First, I’d stop the line immediately and notify my supervisor. Safety and quality are non-negotiable—even if stopping saves just one customer from receiving a defective product, it’s worth it. Then, I would:

- Document the defect: What’s wrong, when it was detected, which product batch it’s from

- Isolate affected units: Ensure similar defects aren’t already shipped

- Trace the root cause: Did the defect occur during assembly, machining, or quality control? Where did we miss it?

- Report findings: Inform the quality team and production manager so they can take corrective action

- Learn from it: Ensure the same mistake doesn’t happen again by either improving the process or training

I understand that in manufacturing, one defect reaching a customer can damage the company’s reputation. So, I’d rather delay production by 30 minutes than compromise quality.”

Why this works? You prioritize safety and quality, show systematic thinking, and demonstrate understanding of real manufacturing consequences.

Q3: "Tell us about a time you improved a process or suggested an idea that was implemented."

Why they ask: They want people who think beyond just “doing their job.”

Strong answer:

“During my 3-month internship at [Company], I noticed that the production team manually tracked daily output on paper—production numbers, defects, downtime. This was then typed into Excel sheets at the end of each shift. It was time-consuming and error-prone.

I suggested we create a simple shared Google Sheet where each shift supervisor could update production data in real-time. Benefits:

- Real-time visibility: Management could see production status anytime

- Reduced errors: No re-typing or manual transcription mistakes

- Time savings: About 45 minutes daily per supervisor

- Better decision-making: Issues could be spotted and addressed faster

I created the template, trained two supervisors, and it was implemented across two production lines. Feedback was positive, and the idea was eventually scaled to all lines. What I learned: Sometimes the best ideas aren’t complicated—they’re about using available tools smartly.”

Why this works? You solve real problems, think like an owner, and show practical contribution value.

Q4: "Why are you interested in manufacturing? You could join tech or finance."

Why they ask: Manufacturing passion is rare among freshers. They want to know if you’re committed or just job-hunting.

Strong answer:

“I love manufacturing because it’s tangible. In tech, you build software; in manufacturing, you build things people physically use and depend on. When I interned at [Company], I saw how a production engineer’s idea for a better assembly sequence improved output by 10%—that’s thousands of products reaching more people. It’s directly impactful.

Plus, manufacturing is undergoing massive transformation. Automation, AI, Industry 4.0—these aren’t future concepts; they’re already here. I want to be part of that transformation, where I bridge the gap between traditional manufacturing and modern technology.

Also, the growth trajectory is clear. A fresher can become a production engineer, then a plant manager within 5-7 years. That kind of structured growth and the ability to develop deep expertise appeals to me more than jumping between startups.”

Why this works? You show genuine interest, awareness of industry transformation, and realistic career thinking.

Q5: "What's your biggest weakness?"

Why they ask: They want honesty and to see if you’re self-aware and committed to improvement.

Smart answer:

“I can be overly detail-oriented sometimes. When I first started working on production documentation, I spent too much time perfecting every detail, which slowed me down. My supervisor pointed this out, and I realized that in manufacturing, ‘good enough with speed’ is sometimes better than ‘perfect but late.’

I’ve worked on this by prioritizing what details truly matter (safety-critical information vs. formatting) and using checklists to ensure I don’t miss important items while moving faster. I’m still learning this balance.”

Why this works? You’re honest, you show self-awareness, you demonstrate improvement, and your weakness is actually somewhat relevant in manufacturing.

Q6: "What do you know about our company?"

Why they ask: They want to see if you did basic research or applied randomly.

Before the interview, research:

- What does the company manufacture?

- Who are their major customers?

- Any recent news (new products, expansions, awards)?

- Company values and what they claim to stand for

- If they have sustainability or Industry 4.0 initiatives

Strong answer:

“[Company Name] manufactures [products] and is known for quality standards and innovation. I read about your recent expansion into [new facility], and I’m impressed by your commitment to Industry 4.0 adoption. Your focus on lean manufacturing aligns with my interest in process optimization. Additionally, your corporate social responsibility initiatives in local communities in Telangana resonate with me. I’m excited about the opportunity to contribute to both the technical excellence and growth trajectory you’ve established.”

Acing Your First 90 Days in Manufacturing

Week 1-2: The Orientation Phase

Advanced Techniques for Standing Out

Goals:

- Learn your company’s culture, values, and specific processes

- Build relationships with your immediate team

- Understand safety procedures deeply

- Get familiar with equipment and facilities

Action items:

- Complete all mandatory training (safety, HR policies, IT systems)

- Shadow your supervisor for at least 2-3 shifts

- Ask questions, take notes (people love when freshers are eager to learn)

- Remember names and small details about teammates (builds rapport)

- Be on time, every single day (Reliability builds respect immediately)

Red flag to avoid: Don’t suggest changes yet. In week 1, you don’t understand enough.

Week 3-4: The Learning & Integration Phase

Goals:

- Become semi-independent in your assigned tasks

- Understand how your role connects to the bigger operation

- Identify your learning gaps

Action items:

- Work without supervision on core tasks, but check in regularly

- Ask mentoring questions: “Why do we do it this way instead of that way?”

- Observe different shifts, processes, and how different teams work

- Start maintaining a “learning journal”—document processes, best practices, and questions

- Engage in informal conversations with colleagues during breaks

Red flag to avoid: Don’t pretend to understand something you don’t. Admit confusion early.

Month 2: The Contribution Phase

Goals:

- Become fully competent in your primary tasks

- Contribute positively to team metrics

- Start identifying improvement opportunities

Action items:

- Take ownership of your assigned responsibilities

- Deliver quality output consistently

- Help teammates when possible

- Attend all production meetings and understand KPIs (Key Performance Indicators) your team tracks

- Start documenting processes you learn—even in your personal notes

Key metric: By end of month 2, your supervisor should feel confident letting you work with minimal supervision.

Month 3: The Ownership Phase

Goals:

- Be a reliable, trusted team member

- Present one small improvement idea

- Plan your next steps (specialization, certification, advancement)

Action items:

- Propose one process improvement idea (small, actionable, proven to work)

- Get feedback from supervisors on your performance and ask for development areas

- Identify which manufacturing area excites you most (quality, automation, planning, etc.)

- Enroll in one relevant certification or skill development (Lean Green Belt, advanced CAD, etc.)

- Schedule a career discussion with your supervisor

The submission formula for improvement ideas:

text

[Problem]: Currently, [process/task] takes [X time/has Y defects]

[Root cause]: This happens because [reason]

[Solution]: If we [implement this change], we can [benefit]

[Evidence]: In my observation, [data or example supporting this]

[Implementation]: We can pilot this in [timeframe] with [resources]

[Expected result]: This saves [time/money/defects]

Career Advancement: From Fresher to Expert (Your 5-Year Plan)

Manufacturing careers have a beautiful structure. Unlike some fields where advancement is unclear, here’s a realistic 5-year trajectory:

Year 1: Foundation & Competency

- Role: Production Trainee / QC Trainee / Assembly Operator

- Focus: Master your core responsibilities, understand the factory, build relationships

- Expected salary: ₹10,000-20,000/month

- Career milestone: Independent, reliable performer

- Parallel learning: Safety certifications, basic software/tool training

Year 2: Specialization Begins

- Role: Senior Operator / Junior QA Executive / Junior Engineer Trainee

- Focus: Develop expertise in your chosen area, mentor newer team members

- Expected salary: ₹18,000-28,000/month

- Career milestone: Recognized as knowledgeable in your specialty

- Parallel learning: Industry-specific certifications (Lean, Six Sigma, CAD, etc.)

Year 3: Transition to Technical Leadership

- Role: Production Engineer / Quality Executive / Senior Technician

- Focus: Lead small projects, contribute to process improvements, mentor juniors

- Expected salary: ₹28,000-40,000/month

- Career milestone: First leadership experience, demonstrated problem-solving

- Parallel learning: Management fundamentals, advanced technical certifications

Year 4-5: Strategic Contributor

- Role: Senior Production Engineer / Quality Manager / Department Lead (depending on track)

- Focus: Oversee larger initiatives, mentor team members, contribute to strategic decisions

- Expected salary: ₹40,000-60,000/month

- Career milestone: Recognized expert in your area

Parallel learning: Business acumen, cross-functional skills, potential MBA or advanced certifications

Building Your Professional Network in Manufacturing

In manufacturing, who you know matters. Here’s how to build a strong network:

During your current job:

- Attend industry conferences (Most companies sponsor attendance for promising employees)

- Join professional associations like Indian Institution of Industrial Engineers (IIIE), SMTA (India), or sector-specific bodies

- Connect with peers on LinkedIn from companies in your sector

- Participate in production meetings and cross-departmental projects

- Mentor juniors—they remember those who helped them

Online networking:

- LinkedIn groups for manufacturing professionals in India

- Follow manufacturing leaders and engage thoughtfully with their posts

- Participate in online forums related to your specialization

- Share your learning journey (articles, insights about manufacturing)

Real-world networking:

- Attend job fairs and manufacturing expos

- Reconnect with internship supervisors and colleagues who move to other companies

- Attend webinars hosted by companies you admire

- When someone helps you, thank them and offer to help them later

Why networking matters: In 5 years, when you’re ready for your next opportunity, your network provides leads before jobs are even publicly posted. Companies also ask current employees for referrals before posting externally, creating hidden opportunities.

Staying Relevant: Continuous Learning in Manufacturing

Manufacturing is evolving rapidly. Robots replace some jobs but create new opportunities. Data science enters the factory floor. Sustainability becomes non-negotiable. To stay ahead:

Annual learning investments (time & money):

- One technical certification (₹2,000-15,000): Lean Six Sigma, advanced CAD, PLC programming, etc.

- One business skill: Data analysis, project management, effective communication

- Industry updates: Subscribe to manufacturing journals, follow industry news, attend webinars

Resources (Many are free or affordable):

- Udemy courses: ₹300-500 per course

- Coursera: Mix of free audit courses and paid certificates

- YouTube channels: Manufacturing Today India, Siemens automation tutorials, Lean manufacturing series

- LinkedIn Learning: Often free through your employer

- Industry associations: Webinars and publications

The compound effect: Someone who learns one new skill yearly improves by ~12% annually. Over 5 years, that’s 60% more skilled and valuable than someone who doesn’t. That difference shows in salary and opportunities.

Red Flags: When It's Time to Move On

Sometimes, despite your best efforts, a job isn’t right. Here’s how to know when it’s time to look elsewhere:

Red flags:

- No growth opportunity: After 2-3 years, you’re still doing the exact same tasks with no progression

- Toxic culture: Management is dismissive, ideas aren’t valued, mistakes are blamed rather than learned from

- Safety compromised: The company cuts corners on safety protocols

- No learning: You’re not gaining new skills or knowledge

- Exploitation: Unrealistic work hours without compensation, bullying, or harassment

When it’s normal to feel frustrated (don’t leave immediately):

- First 6 months: Learning curve is steep; some frustration is normal

- Difficult projects: Sometimes work is genuinely tough; it’s temporary

- Personality conflicts: Not every colleague will be your friend; work happens anyway

How to decide:

- Talk to mentors outside your company

- Give it honest 12-18 months before concluding it’s not right

- Look externally while still employed (never resign first, then search)

When you find a better opportunity, take it confidently—manufacturing is big enough that you can move between companies

PART 8 CONCLUSION: Your First Steps Tomorrow

Your action items for the next 30 days:

- Week 1:

- Update your resume using the framework above

- Optimize your LinkedIn profile

- Identify 5 manufacturing companies in Telangana/Andhra Pradesh where you’d like to work

- Update your resume using the framework above

- Week 2:

- Enroll in one free certification (Lean basics, OSHA safety, CAD fundamentals)

- Research 3 companies—understand what they manufacture and their recent growth

- Reach out to 3-5 people working in manufacturing on LinkedIn—ask for 15-minute coffee chat to learn about their career

- Enroll in one free certification (Lean basics, OSHA safety, CAD fundamentals)

- Week 3:

- Apply to 5-8 manufacturing roles (graduate trainee, production trainee, QC trainee)

- Prepare answers to the 6 common interview questions mentioned above

- Request recommendations from college professors or internship supervisors

- Apply to 5-8 manufacturing roles (graduate trainee, production trainee, QC trainee)

- Week 4:

- Follow up on applications (1 week after applying, check with HR)

- Take at least 2 informational interviews—learn about real jobs from real people

- Follow up on applications (1 week after applying, check with HR)

Refine your elevator pitch: “Hi, I’m [Name]. I’m a [qualification] interested in manufacturing because [reason]. I’m actively seeking [role] to contribute to operational excellence.”

The big picture: Manufacturing isn’t just factories and machines anymore. It’s a sophisticated, evolving, technology-driven industry where freshers with the right mindset and skills can build outstanding careers. The salaries are competitive, the growth is real, and the work is genuinely impactful.

Your competitive advantage: Most freshers view manufacturing as a fallback. You now view it as a deliberate career choice with clear pathways, growth potential, and genuine opportunity. That mindset alone sets you apart.

The honest truth: Like any career, your first 2-3 years will test you. There will be difficult shifts, frustrating processes, and moments when you question your choice. But here’s what happens after that: You become valuable. You develop expertise. You understand systems that most people never will. And suddenly, opportunities multiply—better companies want you, higher positions open up, and your salary trajectory accelerates.

Your next move: Don’t wait for the “perfect” opportunity. Take the first step. Apply for that production trainee role. Take that certification course. Reach out to that manufacturing professional. Small consistent actions compound into career transformation.

Manufacturing needs skilled, thinking, committed professionals like you. The industry is waiting. Your career awaits.

Complete Manufacturing Industry Career Guide Summary

Exercise 1: The Role-Specific Customization Exercise

This comprehensive 8-part guide covered:

- Part 1: Understanding the modern manufacturing industry and why it’s valuable

- Part 2: Manufacturing career roles from entry-level to leadership

- Part 3: Essential hard skills and soft skills needed

- Part 4: Qualification paths and government support programs

- Part 5: Salary progression and earning potential

- Part 6: Government training schemes and support

- Part 7: Real success stories and practical tips

- Part 8: Resume optimization, interview preparation, and career acceleration strategies

Key takeaway: Manufacturing careers offer structured growth, competitive salaries, real-world impact, and clear advancement pathways for freshers willing to invest in learning and contribute meaningfully to their teams.