CNC Programmer—The Machine Language Expert

Table of Contents

The Person Who Tells Machines What to Do: CNC Programmer

A CNC machine can manufacture parts with incredible precision. But it needs instructions. Those instructions are G-code—a specialized programming language. CNC programmers write this code.

They earn ₹30,000-48,000/month as entry-level programmers, advancing to ₹65,000-1,00,000+/month within 5-7 years as specialists or leaders.

What CNC Programmers Actually Do:

Vikram, CNC Programmer at a precision manufacturing facility, receives an order: “Manufacture 10,000 automotive sensor housings from aluminum.”

Step 1: Analyze the Part (1 hour)

- Studies technical drawings

- Identifies dimensions, tolerances, surface finish requirements

- Determines machining operations needed: cutting, drilling, reaming, threading

- Plans sequence (which operations first?)

- Considers tool availability

- Estimates time per part

Step 2: Design Machining Strategy (2 hours)

- Determines optimal tool paths (how CNC moves the cutting tool)

- Selects cutting speeds and feed rates (how fast to cut without breaking tools)

- Plans tool changes (machine might use 5-10 different tools)

- Designs clamp strategy (how to hold part securely)

- Plans coolant flow (some cuts need cooling liquid)

- Ensures optimal cycle time

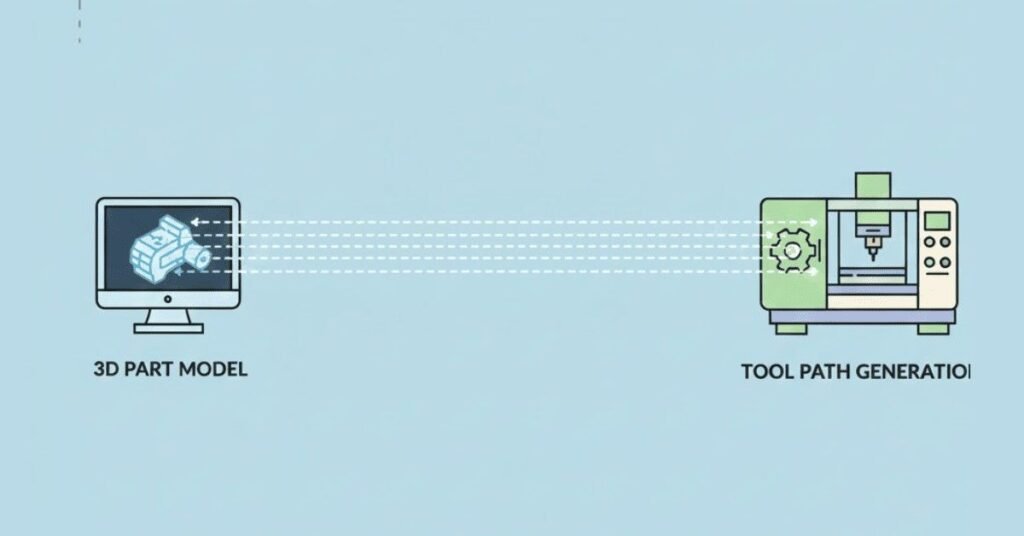

Step 3: CAM Programming (3 hours)

Uses CAM (Computer-Aided Manufacturing) software:

- Imports part design from CAD file

- Visualizes 3D model

- Defines tool paths graphically

- Sets machine parameters (speeds, feeds, depths)

- Simulates cutting process (verify no collisions, no tool breakage)

- Software generates G-code automatically

- Reviews G-code for accuracy

Step 4: Machine Simulation (1 hour)

- Simulates program on CNC simulator software

- Verifies tool paths are correct

- Checks cycle time (does it match estimate?)

- Identifies any issues before running on actual machine

- Makes adjustments if needed

Step 5: Machine Setup & Testing (2 hours)

- Sets up CNC machine with correct tools

- Loads program into machine controller

- Runs first test part slowly (5% speed)

- Verifies dimensions match specifications

- Checks surface finish

- Adjusts program parameters if needed

- Makes second test part at 50% speed

- Final verification

- Ready for production run

Step 6: Production Support (Ongoing)

- Monitors first 100 parts produced

- Checks quality

- Makes fine adjustments if needed

- Trains operators on the program

- Troubleshoots any issues

- Documents final program with notes for future use

Result: 10,000 parts manufactured at spec, cycle time: 3.2 minutes/part, zero defects in first batch

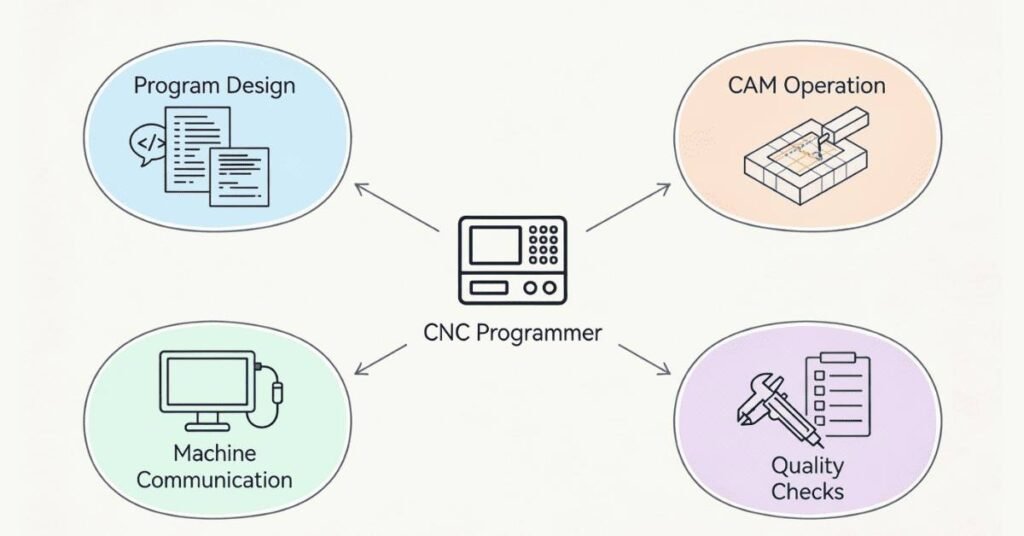

Key Responsibilities of CNC Programmer

Program Design (40%):

- Analyze part drawings

- Determine machining strategy

- Design optimal tool paths

- Select cutting parameters

- Create CNC programs

CAM Software Operation (30%):

- Use CAM software proficiently

- Generate tool paths

- Simulate programs

- Modify programs for optimization

- Troubleshoot software issues

Machine Communication (20%):

- Communicate with machine operators

- Provide setup instructions

- Support machine operation

- Make program adjustments

- Train operators

Quality Assurance (10%):

- Verify program produces parts to specification

- Check first parts for accuracy

- Troubleshoot quality issues

Document final programs

Technical Skills You Need

Core Programming Skills:

- G-Code Programming (Critical)

- G-code language (ISO 1348 standard)

- Coordinate systems (X, Y, Z axes)

- Tool commands

- Speed/feed control codes

- Coolant control

- Why: G-code is CNC machine language

- Learning: 40-60 hours practice-based

- ROI: Essential for this role

- CAM Software (Critical)

- SolidCAM, Mastercam, Fusion 360 CAM, etc.

- 3D tool path generation

- Simulation and verification

- Post-processing (converting CAM output to G-code)

- Why: Professional programmers use CAM, not manual G-code

- Learning: 60-100 hours formal training

- ROI: Essential for modern CNC programming

- CNC Machine Knowledge (Critical)

- Understanding different machine types (mills, lathes, 5-axis machines)

- Machine capabilities and limitations

- Tool systems and tool holders

- Coolant systems

- Control systems (Fanuc, Siemens, Haas, etc.)

- Why: Different machines have different programming requirements

- Learning: 30-50 hours per machine type

- Technical Drawing Interpretation (Important)

- Read and understand engineering drawings

- Understand tolerances and dimensions

- Recognize surface finish symbols

- Interpret GD&T (Geometric Dimensioning & Tolerancing)

- Why: Program must match drawing specifications exactly

- Learning: 20-30 hours

- Tool & Machining Knowledge (Important)

- Cutting tool types and applications

- Cutting speeds and feed rates for different materials

- Tool geometry and angles

- Coolant selection

- Why: Determines program parameters (speed, feed, coolant)

- Learning: 30-40 hours

Additional Skills:

- 5-axis programming (complex parts requiring simultaneous multi-axis movement)

- Wire EDM programming (cutting with electrical discharge)

- Multi-task programming (programs using multiple machines simultaneously)

Manual G-code writing (for simple programs or emergency situations)

Salary Expectations for CNC Programmer

Entry-Level CNC Programmer (No Experience):

₹26,000 – ₹38,000/month

CNC Programmer (1-2 Years Experience):

₹38,000 – ₹55,000/month

Senior CNC Programmer (3-5 Years):

₹55,000 – ₹80,000/month

Lead CNC Programmer / CNC Specialist (5-7 Years):

₹80,000 – ₹1,15,000/month

CNC Programming Manager / Technical Lead (7+ Years):

₹1,15,000 – ₹1,65,000+/month

Why Salaries Grow Fast:

- Specialization: Deep expertise in one area commands premium

- Experience multiplier: 5-axis programming, exotic materials, complex parts earn more

- Efficiency impact: Optimized programs save company money (faster cycle times)

Training value: Experienced programmers train newer staf

How to Enter CNC Programming

Path 1: CNC Machine Operator to Programmer (Recommended)

- Start as CNC machine operator (₹20,000-28,000/month)

- Work 1-2 years: Learn machines, understand operations deeply

- Develop programming interest: Start learning CAM software

- Pursue CAM certification (₹30,000-60,000, 2-3 months)

- Transition to CNC programmer role (₹35,000-48,000/month)

Path 2: Diploma/Degree + Direct Entry

- Complete polytechnic diploma in mechanical or production engineering (3 years)

- Learn CAM software (3-4 months)

- Enter as CNC programmer (₹30,000-42,000/month)

Path 3: Accelerated Program

- CNC programming certification course (3-6 months)

- Includes G-code, CAM software, hands-on practice

- Cost: ₹40,000-80,000

- Includes G-code, CAM software, hands-on practice

Entry salary: ₹28,000-40,000/month

Certifications That Boost CNC Programmer Career

CAM Software Certifications:

- Mastercam Certified Specialist: +₹5,000-10,000/month salary

- SolidCAM Certified: +₹4,000-8,000/month

- Cost: ₹30,000-60,000

- Duration: 4-8 weeks

Advanced Programming Certifications:

- 5-Axis CNC Programming: +₹8,000-15,000/month

- Multi-Task/Mill-Turn Programming: +₹6,000-12,000/month

- Wire EDM Programming: +₹5,000-10,000/month

Machine-Specific Certifications:

- Haas CNC Certified: +₹4,000-8,000/month

- Fanuc CNC Certified: +₹4,000-8,000/month

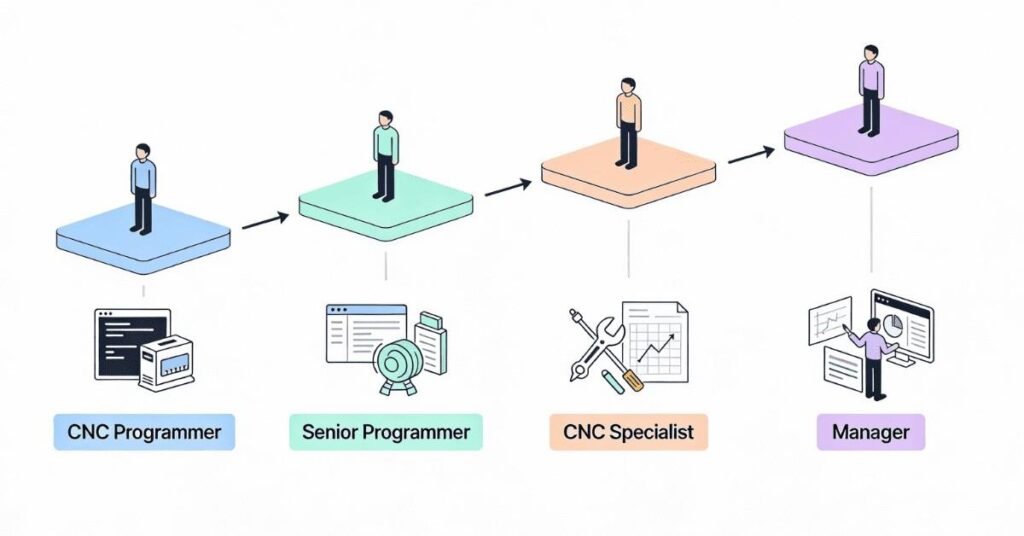

Career Progression: Programmer to Manager

Year 1-2: CNC Programmer

- Learn programming basics, CAM software

- Produce simple programs

- Salary: ₹30,000-42,000/month

Year 3-4: Senior Programmer

- Specialize in complex parts

- Mentor junior programmers

- Optimize programs for efficiency

- Salary: ₹50,000-70,000/month

Year 5-7: Lead/CNC Specialist

- Oversee programming team

- Handle most complex programming

- Strategy for CNC operations

- Salary: ₹75,000-1,15,000/month

Year 8+: Manager/Director

- Manage CNC operations team

- Strategic planning

- Salary: ₹1,15,000-1,80,000+/month

The Bottom Line: CNC Programmer is Precision Engineering Career

CNC programmers are essential to precision manufacturing. Entry salary ₹30,000-42,000 → 5-year salary ₹75,000-1,15,000. The work is intellectually engaging (solving complex programming challenges), directly impacts quality and efficiency, and advancement is clear.

If you enjoy problem-solving, CAD/CAM software, and precision manufacturing, CNC programming is your path.