Assembly Operator—Your First Manufacturing Role

Table of Contents

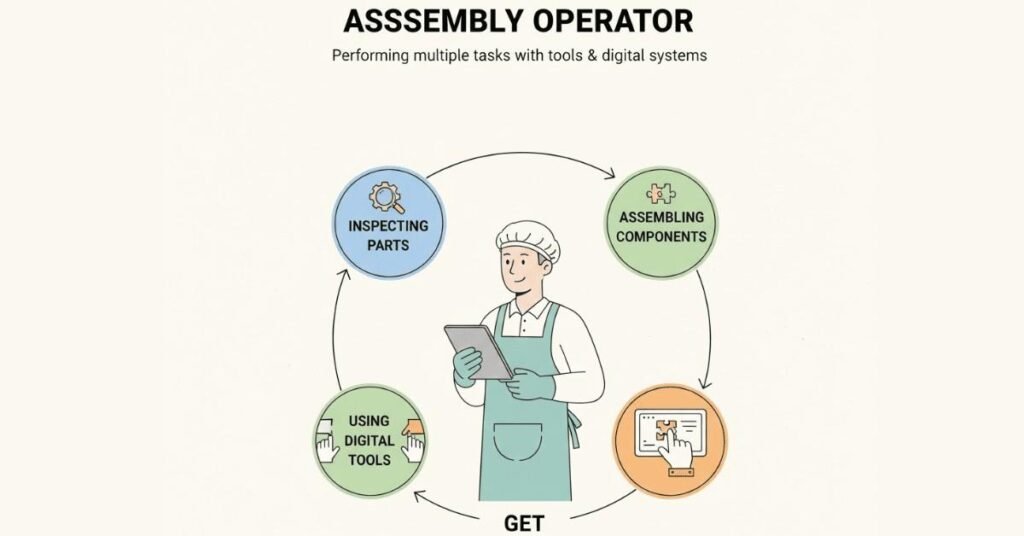

What Does an Assembly Operator Actually Do?

Close your eyes and picture an assembly operator. Most people imagine someone robotically placing parts together, repeating the same motion thousands of times daily.

That image is partially correct but deeply incomplete.

Modern assembly operators in 2025 are far more than repetitive workers. They’re quality gatekeepers, system monitors, problem-solvers, and often the first people to identify issues that could affect thousands of customers. Let’s understand what the job actually entails.

The Real Daily Work of an Assembly Operator

Morning (7:00 AM – 10:00 AM):

An assembly operator named Priya arrives at 6:45 AM for a 7:00 AM shift in an automotive component facility. First, she logs into the production system using her credentials. The system shows her:

- Which products are scheduled for assembly today (work order from central planning)

- Quality standards for each product

- Any special instructions or changes from yesterday

- How many units she needs to complete

By 7:00 AM, she receives a safety briefing (5 minutes) covering:

- Any safety incidents from previous shifts

- Equipment that’s acting unusual

- New procedures or changes

- Goal reminders

She inspects her workstation:

- Are all required tools present and functioning?

- Is the work surface clean?

- Are assembly materials (components) properly organized?

- Does equipment display any warning lights?

Production begins. Priya receives the first batch of components. She follows the digital work instructions displayed on a tablet:

- Inspect incoming components for visible defects

- Assemble components in exact sequence shown

- Use calibrated tools (torque wrenches that ensure exact tightness)

- Take a photo of the completed assembly using a fixed camera

- Place the assembled product in the quality queue

Each assembly takes 8-12 minutes. She completes about 5 units per hour. But—and this is crucial—she’s not just mindlessly repeating. She’s:

- Monitoring for quality issues

- Reporting unusual component problems

- Ensuring every step follows procedure

- Watching for safety concerns

- Communicating with team members

Mid-Morning (10:00 AM – 12:30 PM):

Around 10:30 AM, Priya notices a component isn’t fitting correctly on three consecutive units. Instead of ignoring it or forcing it, she:

- Stops her line immediately

- Alerts her supervisor using the system

- Documents the issue (photo, description)

- Waits for supervisor to investigate

Investigation reveals the components have a dimensional issue (they’re slightly oversized). The supervisor contacts the receiving/quality team. They identify the supplier error. Components are quarantined. An alternate batch is provided. Production resumes within 30 minutes.

This is a critical skill: knowing when to stop, reporting issues, and preventing bad products from reaching customers.

She takes a 30-minute lunch break (typically 12:30 PM – 1:00 PM).

Afternoon (1:00 PM – 5:00 PM):

Production resumes. By 3:00 PM, the team has completed 180 units (goal: 200/day). Priya continues assembly until 4:45 PM.

At 4:45 PM, she:

- Cleans her workstation thoroughly

- Completes a production report (units completed, issues encountered, next operator notes)

- Logs out of the system

- Hands over to the evening shift operator

Total units today: 198 (98% of target). Zero defects on her line. One proactive issue identification. Excellent shift.

Why This Detailed Daily? Because It Shows the Real Job

Notice what Priya did:

- She used technology (systems, tablets, photos)

- She made decisions (when to stop the line)

- She communicated (reporting issues)

- She took responsibility (quality, safety, efficiency)

- She solved problems (identifying component issues)

This is modern assembly work. It’s not mindless. It’s engaged, responsible, thinking work.

Key Responsibilities of Assembly Operators

Quality Responsibility (Most Critical):

- Inspect incoming components before assembly

- Follow assembly procedures exactly as specified

- Verify assembled products meet dimensional standards

- Report quality issues immediately

- Document quality findings

- Contribute to zero-defect culture

Production Responsibility:

- Complete assigned units within quality standards

- Meet daily production targets

- Maintain consistent pace and output

- Optimize workflow without compromising quality

- Report and document all production challenges

Safety Responsibility:

- Follow all safety procedures without exception

- Use personal protective equipment (PPE) correctly

- Report safety hazards immediately

- Participate in safety meetings and training

- Look out for teammates’ safety

Communication Responsibility:

- Report problems to supervisors promptly

- Communicate with quality and maintenance teams

- Collaborate with other operators

- Participate in daily team meetings

- Suggest improvements

System Responsibility:

- Use production systems correctly

- Enter data accurately

- Follow digital work instructions

- Report system glitches

Maintain digital documentation

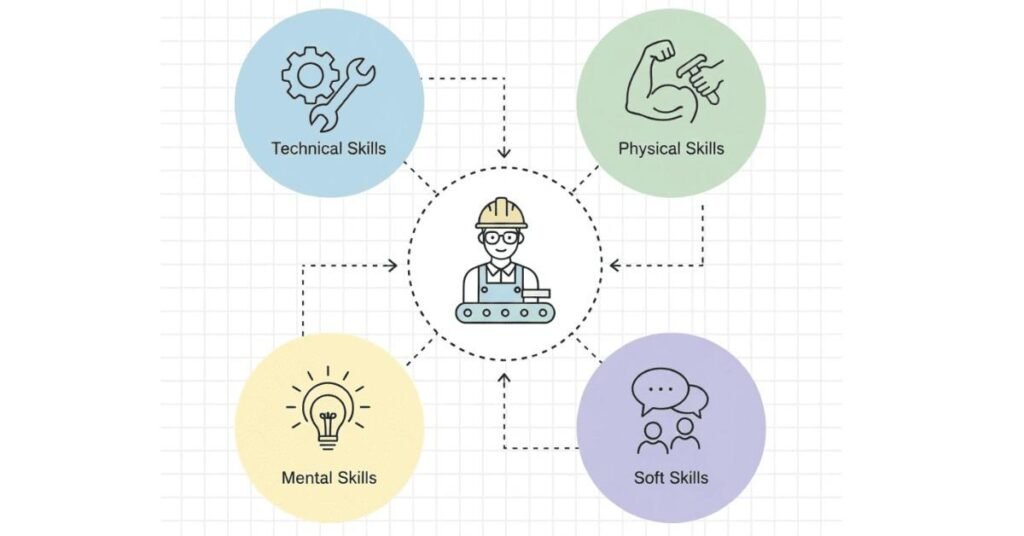

Skills You Actually Need (Not Just Technical)

Technical Skills:

- Basic understanding of manufacturing processes

- Ability to use hand tools (screwdrivers, wrenches, torque wrenches)

- Reading and interpreting technical drawings

- Understanding quality standards and measurements

- Using basic systems and tablets

- Following precise procedures

Physical Skills:

- Standing for 8 hours (most shifts are on your feet)

- Repetitive hand/arm movements (without developing strain)

- Lifting up to 15-20 kg regularly

- Fine motor coordination (precise assembly)

- Ability to work in industrial environments (noise, heat)

Mental/Analytical Skills:

- Attention to detail (spotting defects others miss)

- Problem-solving (identifying when something’s wrong)

- Decision-making (when to stop, when to report)

- Learning ability (quickly understanding procedures)

- Patience (work is sometimes repetitive, requires focus)

Soft Skills:

- Communication (reporting issues clearly)

- Teamwork (collaborating with colleagues)

- Reliability (showing up, being consistent)

- Willingness to learn (accepting corrections, improving)

- Responsibility (taking work seriously)

Skills You DON’T Necessarily Need:

- Previous manufacturing experience (will be trained)

- Advanced education(12th pass is sufficient)

- Engineering knowledge (basic math is enough)

- Specific technical certifications (learned on-job

Salary Expectations: What You'll Actually Earn

Starting Salary Range:

₹10,000 – ₹15,000 per month (base salary)

Actual Take-Home (With Components):

- Base: ₹12,000

- Shift allowance (if night shift): +₹1,500-2,000

- Production bonus (based on targets achieved): +₹1,500-3,000

- Attendance bonus: +₹500-1,000

- Actual monthly: ₹15,000-20,000

After 1-2 Years (With Promotion to Senior Operator):

₹18,000 – ₹26,000 per month

Factors Affecting Your Salary:

- Performance: Quality and productivity bonuses

- Attendance: Perfect attendance earns rewards

- Shift timing: Night shifts pay more than day shifts

- Company size: Larger companies typically pay more

- Location: Cities pay more than towns

- Industry sector: Automotive and electronics pay better than textiles

Additional Benefits (Beyond Salary):

- Health insurance (for you and often family)

- Provident fund (retirement savings)

- Paid leave (typically 8-12 days/year)

- Performance bonus (typically 1-3 months salary/year)

- Accident insurance

Skills training programs

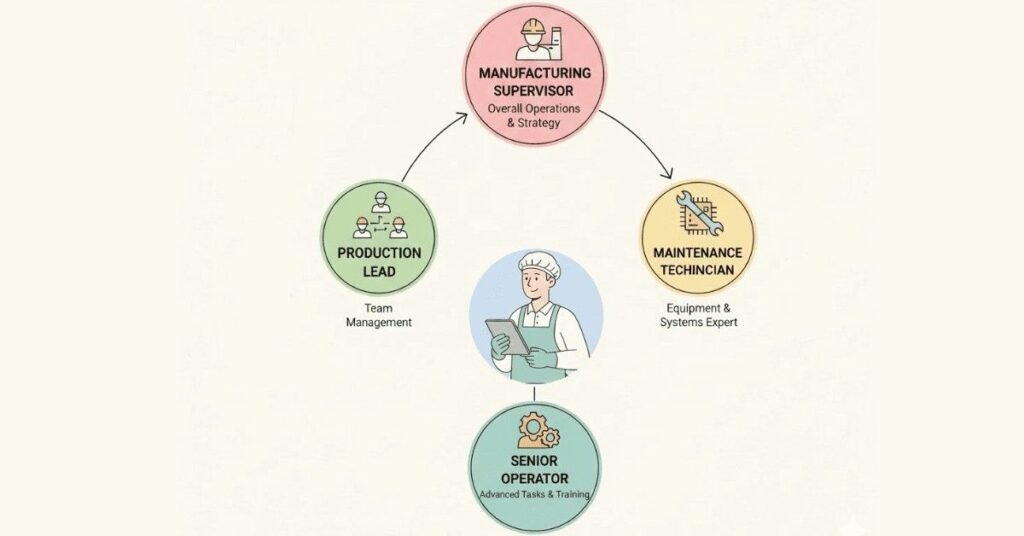

The Career Progression: From Operator to Supervisor

This is the exciting part. Assembly operators don’t get stuck in the same role forever. Here’s the typical progression:

Year 1: Assembly Operator

- Salary: ₹12,000-15,000/month

- Focus: Learning the role, proving reliability

- Goal: Become independent, mistake-free operator

Year 2: Senior Assembly Operator

- Salary: ₹18,000-24,000/month

- Responsibilities: Mentoring new operators, quality leadership, process suggestions

- Goal: Demonstrate leadership potential

Year 3: Shift Lead / Line Lead

- Salary: ₹24,000-32,000/month

- Responsibilities: Supervising 8-12 operators, ensuring production targets, quality management

- Goal: Prove supervisory capability

Year 4-5: Shift Supervisor

- Salary: ₹32,000-45,000/month

- Responsibilities: Managing entire shift, planning, coordination, hiring/training

- Goal: Potential for senior supervisory or management roles

Year 5+: Senior Supervisor / Assistant Manager

- Salary: ₹45,000-65,000+/month

- Responsibilities: Multiple departments, strategic planning, leadership development

Notice the progression: Entry salary ₹12,000 → 5-year salary ₹50,000+. That’s a 4x increase in five years, not through changing jobs, but through growing within manufacturing.

What This Means: A fresher who starts as an assembly operator and demonstrates reliability, problem-solving, and willingness to learn can reach supervisory positions earning ₹40,000-50,000/month within 5 years, without needing to leave the manufacturing floor.

Types of Assembly You Might Do

Assembly isn’t uniform. Different industries require different assembly types:

Automotive Assembly:

- Engine components, transmissions

- Car interiors, wiring harnesses

- Two-wheeler frames, engines

- Typically complex, high precision

Electronics Assembly:

- Circuit board components

- Consumer electronics (phones, laptops)

- Computer peripherals

- Requires precision and clean environment

Pharmaceutical Packaging:

- Packing medicines, tablets

- Labeling bottles, cartons

- Sterile environments required

- High accuracy for correct dosage

Food Processing Assembly:

- Packaging products

- Mixing, filling processes

- Weighing and portion control

- Hygiene emphasis

Appliance Assembly:

- Refrigerators, washing machines

- Smaller appliances

- Mix of mechanical and assembly

- Customer-visible components

Which Type is Right for You?

- If you like precision: Electronics or automotive

- If you prefer less environmental stress: Food or appliance

- If you want higher salary: Automotive or electronics

If you want easier entry: Food or appliance

Day-to-Day Challenges You'll Face

Physical Challenges:

- Repetitive motion strain (mitigated by proper ergonomics and breaks)

- Standing for long hours (shoes and stretching help)

- Occasional heavy lifting (teams usually help with heavy items)

- Heat in some facilities (ventilation exists but summer can be hot)

Mental Challenges:

- Monotony (same tasks repeatedly, though problems keep it interesting)

- Pressure to meet targets (but targets are designed to be achievable)

- Responsibility for quality (pressure to maintain zero-defect standards)

- Attention focus needed (concentration throughout shift)

Social Challenges:

- Shift work disrupts social life (adjusting to night shifts)

- Noisy environment (hearing protection provided)

- Limited interaction (assembly is focused work, not highly social)

- Team dynamics (as with any workplace)

Real Talk: These challenges are manageable. Millions of assembly operators work sustainably for decades. The key is choosing a facility and role that aligns with your preferences.

Why Assembly Operator is Your Best Fresher Entry

Advantages:

- Guaranteed learning: You’re trained comprehensively

- Immediate earning: You’re paid from day 1 (not unpaid internship)

- Clear advancement: You see how to progress

- Foundation building: You understand manufacturing fundamentals

- Job security: If you perform, you’re valuable

- No college degree required: 12th pass is sufficient

When Assembly Operator Might Not Be Ideal:

- If you’re not comfortable standing 8 hours daily

- If you’re unable to work shifts

- If you strongly prefer office environments

- If you have severe repetitive strain issues

If you prefer highly varied daily tasks

How to Land Your First Assembly Operator Role

Application Strategy:

- Identify manufacturing facilities in Telangana (automotive, electronics, food processing)

- Apply directly through their careers website or visit in person

- Mention your reliability and willingness to learn (not previous experience—you don’t have it)

- Prepare for interviews by understanding the company’s products

Interview Tips:

- Research the company’s products

- Emphasize reliability and learning attitude

- Show enthusiasm for manufacturing

- Ask about training and advancement opportunities

- Be honest about any limitations (shift work, physical capabilities)

Day 1 Preparation:

- Comfortable closed-toe shoes (you’re on your feet 8 hours)

- Safety glasses (provided, but comfortable fit matters)

- Casual work clothes (no fancy dress)

- Confidence that you can learn