Robotics Engineer—The Automation Designer

Table of Contents

From Technician to Engineer: The Strategic Leap

An automation technician installs and maintains robots. A robotics engineer designs and innovates robots. The difference: one follows existing solutions; the other creates new ones.

Robotics engineers earn ₹50,000-75,000/month as entry-level engineers, advancing to ₹1,00,000-1,80,000+/month within 8-10 years in senior roles. They lead the automation strategy for entire facilities. They design the robots of tomorrow.

What Robotics Engineers Actually Do:

Priya, Robotics Engineer at a manufacturing facility, faces a challenge: Assembly line is too slow. Current manual assembly: 200 units/day. Goal: 500 units/day with zero quality compromises.

Her solution: Design a robotic assembly system from scratch.

Phase 1: Requirement Analysis (Week 1-2)

- Studies the assembly process in detail

- Identifies which steps can be automated (assembly, placement, fastening)

- Determines precision requirements (tolerances needed)

- Calculates cycle time needed (to achieve 500 units/day)

- Estimates budget (₹1 crore for equipment)

- Evaluates available space (factory floor layout)

Phase 2: Conceptual Design (Week 3-4)

- Sketches robotic system layout using CAD

- Selects robot type (articulated arms, collaborative robots)

- Determines number of robots needed (simulation shows 3 robots handle the load)

- Designs end-effectors (grippers, tools) for specific assembly tasks

- Plans integration with conveyor, material handling systems

- Calculates ROI (₹1 crore investment saves ₹3 crore annually = 4-month payback)

Phase 3: Detailed Design (Week 5-8)

- Creates technical drawings using CAD/CAM software

- Designs safety systems (collision detection, emergency stops)

- Plans electrical and compressed air connections

- Designs material feeding systems (components reach robot at right time)

- Creates detailed specifications for procurement

- Documents all design decisions with reasoning

Phase 4: Simulation & Optimization (Week 9-12)

- Simulates robot movements in software (ensures feasibility)

- Tests cycle time in simulation (will it really achieve 500 units/day?)

- Identifies potential issues before hardware arrives

- Optimizes movements to reduce cycle time further (simulation shows 2.8 seconds/unit instead of 3 seconds)

- Verifies safety scenarios in simulation

- Plans training documentation

Phase 5: Implementation & Commissioning (Month 4-5)

- Oversees robot installation

- Tests integrated system

- Troubleshoots any issues

- Optimizes final parameters

- Trains operators and maintenance staff

- Validates final performance

Result: System produces 520 units/day (exceeds target), ₹3 crore annual savings achieved, payback period: 4 months. Priya’s design is success.

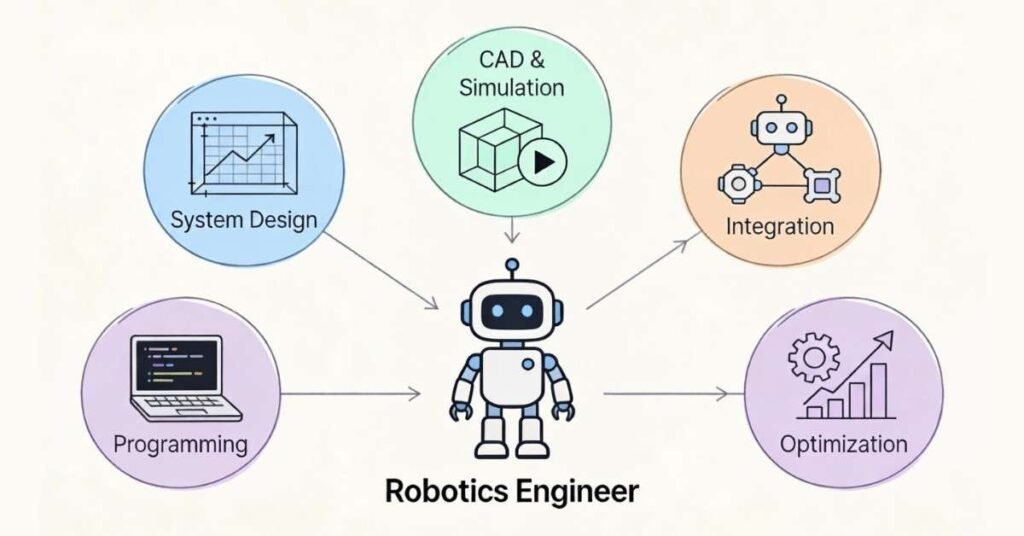

Key Responsibilities of Robotics Engineer

System Design (30%):

- Design robotic automation solutions

- Select appropriate robots for tasks

- Design custom end-effectors and tooling

- Plan system layout and integration

- Create technical specifications

CAD & Simulation (25%):

- Create 3D designs using CAD software

- Simulate robot movements and processes

- Verify designs before hardware procurement

- Design for manufacturability and maintenance

- Optimize designs based on simulations

Implementation & Integration (25%):

- Oversee robot installation

- Integrate with production systems

- Commission and test systems

- Troubleshoot implementation issues

- Optimize system performance

Programming & Optimization (15%):

- Program robot movements and logic

- Optimize cycle times

- Improve accuracy and reliability

- Adapt to new products or process changes

- Document programming

Team Leadership & Training (5%):

- Mentor junior engineers or technicians

- Train operators and maintenance staff

- Lead implementation teams

Communicate with stakeholder

Technical Skills You Must Master

Core Engineering Skills:

- CAD/CAM Software (Critical)

- SolidWorks: Robot system design, 3D modeling

- CATIA: Complex automation systems

- AutoCAD: Layout design, documentation

- Simulation software: Verify designs before building

- Why: Design everything from robot placement to end-effectors

- Learning: 100-150 hours formal training + practice

- ROI: Essential for design work

- Robot Programming (Critical)

- FANUC TPP, ABB RAPID, KUKA KRL language

- Understand kinematics and motion planning

- Path optimization

- Sensor integration

- Why: Program robots to perform tasks safely and efficiently

- Learning: 60-100 hours per robot brand

- ROI: Essential for your role

- Electrical Systems Engineering (Important)

- Power distribution and control

- Motor and drive systems

- Sensor integration

- Safety systems and circuits

- PLC integration

- Why: Robots need electrical systems to operate

- Learning: 40-60 hours

- Mechanical Engineering Fundamentals (Important)

- Mechanics and dynamics

- Material strength and selection

- Mechanical design principles

- Tolerances and precision

- Why: Design mechanical components that work reliably

- Learning: Part of engineering degree

- System Integration (Important)

- Integrate robots with conveyors, quality systems

- Design data communication between systems

- Plan workflow automation

- Ensure seamless operation

- Why: Robots don’t work in isolation; must integrate with factory

- Learning: 30-50 hours + on-job experience

Additional Technical Skills:

- Machine learning basics (emerging: AI optimization of robot movements)

- Vision system design (robots need to “see” to position correctly)

- Safety engineering (ISO 10218 for robotics safety standards)

Project management (oversee robot implementation projects)

Soft Skills for Success

Problem-Solving:

- Design solutions to automation challenges

- Troubleshoot implementation issues

- Optimize performance continuously

- Think creatively about new approaches

Communication:

- Explain complex robotic systems to non-technical managers

- Document designs clearly

- Present recommendations persuasively

- Train operators and maintenance staff

Project Management:

- Oversee robot implementation projects

- Manage timelines and budgets

- Coordinate teams

Track RO

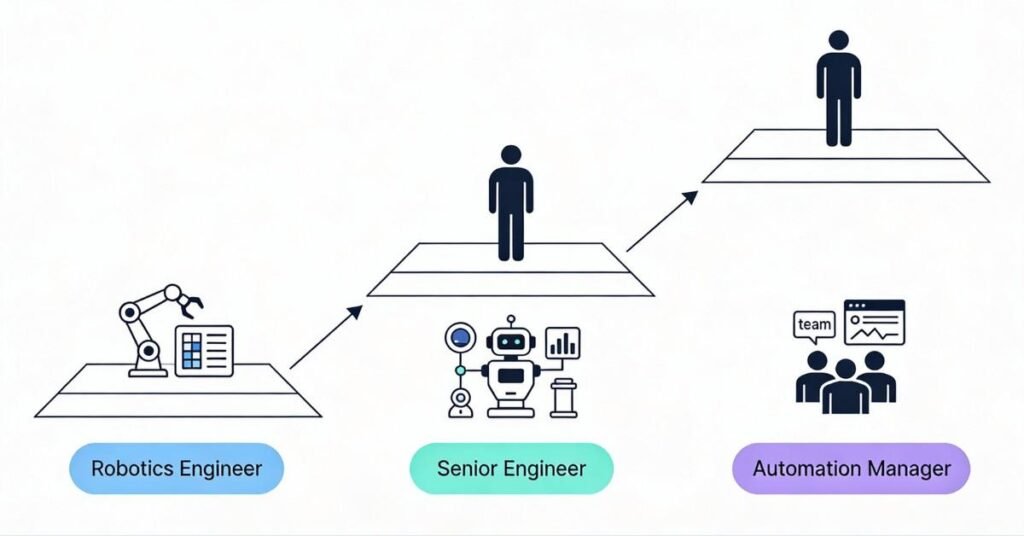

Salary Expectations for Robotics Engineer

Junior Robotics Engineer (Year 0-2):

₹50,000 – ₹75,000/month

Robotics Engineer (Year 2-5):

₹75,000 – ₹1,15,000/month

Senior Robotics Engineer (Year 5-8):

₹1,15,000 – ₹1,60,000/month

Lead/Principal Robotics Engineer (Year 8+):

₹1,60,000 – ₹2,20,000+/month

Robotics Manager / Director:

₹1,80,000 – ₹3,00,000+/month

Why Robotics Salaries Are Premium:

- Specialized expertise: Fewer people design robots; high demand

- Business impact: Automation directly improves productivity; measurable ROI

- Strategic importance: Automation is central to manufacturing future

- Scarcity: Severe shortage of robotics engineers globally

International opportunity: Companies compete globally for talent

How to Enter Robotics Engineering

Path 1: Engineering Degree + Robotics Specialization (Recommended)

- Complete engineering degree: Mechanical, Electronics, or Mechatronics (4 years)

- Pursue robotics specialization: Elective courses, projects focused on robotics

- Develop practical skills: Internship with automation/robotics company

- First role: GET Program or Junior Robotics Engineer (₹50,000-75,000/month)

Path 2: Automation Technician to Engineer

- Work as automation technician (3-5 years)

- Gain deep practical experience

- Pursue engineering diploma or degree (2-3 years, part-time)

- Transition to robotics engineer role (salary increase ₹25,000-40,000/month)

Path 3: Accelerated Program

- Post-graduate certification in robotics (6-12 months)

- Requires engineering degree or equivalent

Entry salary: ₹55,000-70,000/month

Certifications That Boost Robotics Engineer Career

Manufacturer-Specific Certifications:

- FANUC Certified Robotics Programmer

- ABB Certified Robotics Engineer

- KUKA Certified Roboticist

- Benefit: ₹10,000-20,000/month salary bump

- Cost: ₹60,000-1,20,000 per certification

- ROI: Very high; manufacturer certifications highly valued

Advanced Certifications:

- Advanced Robotics & AI (if you pursue machine learning in robotics)

- Safety Systems Design (ISO 10218 specialist)

Vision Systems Integratio

The Bottom Line: Robotics Engineer is Tomorrow's Job

Robotics engineers earn top-tier manufacturing salaries because they design the automation that transforms factories. Entry salary ₹50,000-75,000 → 8-year salary ₹1,60,000+. Work is intellectually engaging, strategically important, and future-proof.

If you’re engineering graduate who loves automation and technology, robotics engineering is your career path.