Production Engineering Track—The Technical Expert Path

Table of Contents

The Person Who Makes Factories Better: Production Engineer

Visit a factory with recurring quality problems—10% defect rate, production consistently 20% below target, frequent equipment breakdowns. The production line looks identical to well-performing factories. Same machines. Same operators. Same materials.

What’s different? The engineer designing the process.

Production engineers are the architects of manufacturing efficiency. They design how products flow through production, optimize processes, solve recurring problems, and continuously improve systems. While supervisors manage people and day-to-day execution, production engineers improve the fundamentals of how manufacturing happens.

Production Engineering is one of the fastest-growing roles in modern manufacturing, with specialization in lean manufacturing and process optimization commanding premium salaries

What Production Engineers Actually Do: The Real Work

Rohit, Production Engineer at a Pharmaceutical Manufacturing Facility

Rohit has been in this role for 2 years. Here’s what his typical week looks like:

Monday: Process Analysis

A batch of tablets is failing final inspection at 15% defect rate (should be <1%). Rohit investigates:

- Collects data: Reviews production logs, quality reports, equipment sensor data

- Maps the process: Documents every step: mixing → granulation → compression → inspection → packaging

- Identifies variations: Notices compression force varies slightly between units (equipment calibration drifting?)

- Tests hypothesis: Requests maintenance check equipment calibration

- Finds root cause: Calibration was indeed off by 2%

- Proposes solution: Implement automated calibration check every 2 hours

- Analyzes impact: If implemented, defects drop to predicted 0.8%

- Cost-benefit: Solution costs ₹2,00,000 implementation, prevents ₹50,00,000 in batch losses annually

Monday conclusion: Rohit presents findings to production manager with data-backed recommendation. Approval to proceed.

Tuesday: Process Redesign

New product launch next month. Current production design uses 8 steps. Rohit wants to streamline it:

- Current state mapping: Documents existing process (wastes time, requires excessive handling)

- Lean analysis: Which steps add value? Which are waste?

- Redesigns process: Consolidates to 6 steps through better sequencing

- Simulates new design: Uses manufacturing software to model new process

- Predicts outcomes: New design should reduce cycle time 20%, reduce defects 15%

- Tests new design: Runs pilot production with new process (100 units)

- Measures results: Results match predictions: 22% cycle time reduction, 18% defect reduction

- Documents: Creates work instructions for new process

Tuesday conclusion: Pilot successful. New process ready for full-scale launch. Rohit will train operators on the new procedure.

Wednesday: Equipment Evaluation

Company considering new automated packaging equipment (₹50,00,000 investment). Rohit’s role: technical evaluation.

- Reviews equipment specifications

- Compares to current process: How much improvement?

- Calculates ROI: Cost vs. savings, payback period

- Requests demo: Works with vendor to test equipment

- Evaluates compatibility: How does new equipment integrate with existing systems?

- Analyzes risks: What could go wrong? How do we mitigate?

- Creates business case: ₹50 lakh investment saves ₹1 crore annually = 5-year payback, then pure profit

Wednesday conclusion: Rohit presents recommendation to management with detailed analysis. Equipment approved.

Thursday: Continuous Improvement Meeting

Rohit leads a cross-functional team: production supervisor, quality manager, maintenance technician, operators.

Agenda: Why is Equipment A consuming more power than last year despite same output?

Investigation:

- Maintenance tech: “Compressor bearings might be wearing”

- Quality manager: “Production parameters haven’t changed”

- Supervisor: “Operators say it sounds different”

- Operators: “Takes longer to reach pressure”

Rohit’s analysis:

- Reviews equipment logs: Startup time increased from 45 seconds to 68 seconds

- Requests bearing replacement

- Tracks energy consumption post-replacement: Returns to normal

- Cost: ₹50,000 preventive maintenance vs. ₹5,00,000 complete equipment replacement

Result: Problem prevented, massive cost savings, team learns to proactively monitor equipment.

Friday: Documentation & Planning

- Updates process documentation with Tuesday’s design changes

- Completes technical reports for Monday and Wednesday initiatives

- Plans next week: New operator training on redesigned process

- Reviews equipment maintenance schedule

- Prepares performance metrics for director meeting

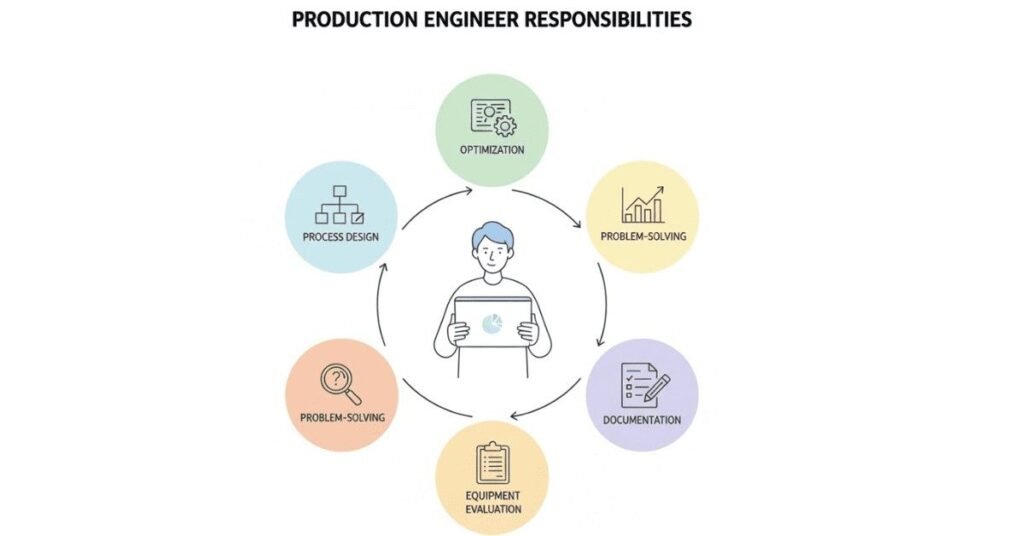

Key Responsibilities of Production Engineers

Process Design & Optimization (35% of role):

- Design efficient production processes

- Use CAD/simulation software

- Apply lean manufacturing principles

- Optimize cycle times and workflows

- Reduce waste and defects

- Design for manufacturability

- Continuously improve processes

Technical Problem-Solving (30% of role):

- Investigate production issues

- Analyze root causes

- Test and implement solutions

- Measure solution effectiveness

- Document learnings

- Prevent recurring problems

- Troubleshoot equipment integration issues

Equipment & Technology Management (20% of role):

- Evaluate new equipment

- Manage equipment implementation

- Ensure equipment operates optimally

- Collaborate with maintenance

- Support equipment selection decisions

- Design equipment setups

- Optimize equipment utilization

Process Documentation & Training (10% of role):

- Create work instruction

- Document procedures

- Train operators on new processes

- Create visual aids and manuals

- Maintain technical documentation

- Communicate changes to team

Continuous Improvement (5% of role):

- Lead improvement initiatives

- Participate in kaizen events

- Implement lean/Six Sigma methodologies

- Mentor operators on improvement thinking

- Share best practices

Technical Skills You Must Master

Core Engineering Skills:

- CAD Software (Critical)

- AutoCAD: Creating 2D drawings, technical designs

- SolidWorks: 3D modeling, process simulation

- CATIA: Advanced design, complex systems

- Why it matters: Design everything from layouts to new equipment configurations

- Learning: 60-80 hours of training + practice

- ROI: Essential skill; companies expect it

- Lean Manufacturing (Essential)

- Understand lean principles (eliminate waste)

- Value stream mapping (visualize process flow)

- 5S methodology (organize workspace)

- Kaizen (continuous improvement)

- Why it matters: 80% of process improvements use lean principles

- Learning: 40-50 hours training, certification available

- ROI: High—companies pay more for lean expertise

- Process Analysis & Statistics (Important)

- Statistical Process Control (SPC)

- Data analysis techniques

- Understanding variation and defects

- Root cause analysis (5-why method, fishbone diagrams)

- Why it matters: Make data-driven decisions, not guesses

- Learning: 30-40 hours training

- ROI: High—differentiates from average engineers

- Manufacturing Execution Systems (MES) (Important)

- Understand how production data flows

- Use MES for monitoring production

- Extract data for analysis

- Why it matters: Modern factories are digital; you need to read production data

- Learning: Company-specific training (20-30 hours)

- ROI: Essential in modern facilities

- Project Management Basics (Useful)

- Planning projects (equipment installation, process changes)

- Managing timelines and budgets

- Coordinating teams

- Why it matters: Larger improvements require project management

- Learning: 20-30 hours training, certifications available

- ROI: Enables advancement to senior roles

Additional Technical Skills:

- Basic electrical knowledge (understand power consumption, wiring)

- Hydraulics/pneumatics (understand fluid systems)

- Safety engineering (OSHA compliance, hazard analysis)

- Quality systems (ISO 9001, statistical quality control)

Maintenance collaboration (understand equipment maintenance

Soft Skills That Make Excellent Engineers

Problem-Solving Mindset:

- See problems as opportunities

- Ask “why” multiple times to find root causes

- Think systematically (analyze vs. guess)

- Test solutions before full implementation

- Learn from failures

Communication Skills:

- Explain technical concepts to non-technical people (operators, managers)

- Document processes clearly

- Present recommendations persuasively

- Listen to frontline insights (operators see things engineers miss)

- Write clear technical reports

Collaboration Ability:

- Work across departments (production, quality, maintenance)

- Earn credibility from operators (they’re the experts on daily realities)

- Build relationships with suppliers and vendors

- Accept feedback and improve designs

- Share knowledge generously

Continuous Learning:

- Stay current with manufacturing technology

- Learn from mistakes

- Pursue certifications proactively

- Read industry publications

Attend conferences and trainings

Salary Expectations for Production Engineer Path

Graduate Engineer Trainee (GET) / Junior Production Engineer (Year 0-1):

₹22,000 – ₹35,000/month

(Fresh from college in GET program)

Production Engineer (Year 1-3):

₹35,000 – ₹55,000/month

(Independent technical work, project leadership)

Senior Production Engineer (Year 3-6):

₹55,000 – ₹85,000/month

(Specialized expertise, multiple projects, mentoring)

Lead/Principal Production Engineer (Year 6-10):

₹80,000 – ₹1,25,000/month

(Strategic projects, department-wide optimization, senior influence)

Production Manager / Engineering Manager (Year 8+):

₹1,00,000 – ₹1,80,000+/month

(Team leadership, budget responsibility, strategic planning)

Salary Acceleration Through Certifications:

- Six Sigma Black Belt: +₹8,000-15,000/month salary bump

- Lean Master: +₹5,000-10,000/month salary bump

- Advanced CAD Certification: +₹3,000-8,000/month salary bump

- MBA (Operations/Manufacturing): +₹20,000-40,000/month salary increase

Why Production Engineer Salaries Grow Fastest:

Compared to supervisory role (which grows slower, caps earlier), production engineers:

- Have specialized, hard-to-replace expertise

- Direct impact on profitability (efficiency improvements = company savings = higher pay)

- Can move to different sectors maintaining salary (unlike supervisor roles specific to facility)

- Command global opportunities (international project assignments, higher pay)

Typical Path: GET ₹25,000 → Senior Engineer ₹75,000 → Manager ₹1,50,000 (in 8-10 years) = 6x salary increase

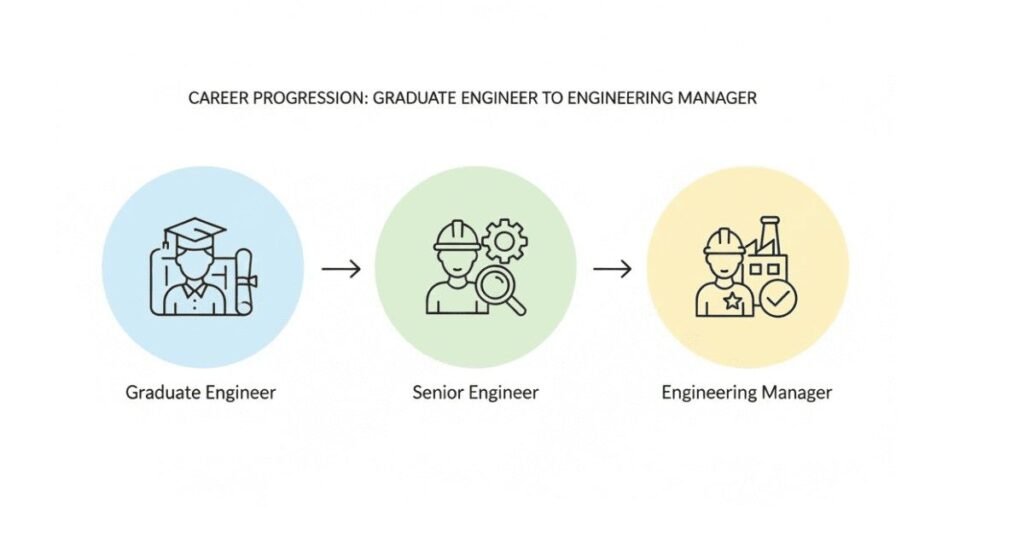

Career Progression: Production Engineer to Senior Leadership

Year 1: Graduate Engineer Trainee / Junior Production Engineer

- Salary: ₹22,000-35,000/month

- Role: Learning manufacturing, assisting on projects, small independent assignments

- Focus: Master fundamentals, build credibility

- Certification goal: CAD basics, Lean intro

Year 2-3: Production Engineer

- Salary: ₹35,000-55,000/month

- Role: Lead process improvements, design processes, technical problem-solving

- Focus: Develop specialized expertise in one area

- Certification goal: Lean Green Belt, CAD advanced, SPC

Year 4-6: Senior Production Engineer

- Salary: ₹55,000-85,000/month

- Role: Strategic process optimization, mentor junior engineers, complex projects

- Focus: Become go-to expert, lead major initiatives

- Certification goal: Lean Black Belt, Project Management, advanced statistics

Year 7-8: Lead Engineer / Principal Engineer

- Salary: ₹80,000-1,25,000/month

- Role: Department-level optimization, cross-facility initiatives, strategic planning

- Focus: Shape company-wide practices, develop other engineers

- Responsibility: Budget, team leadership, strategy

Year 9+: Engineering Manager / Director

- Salary: ₹1,00,000-1,80,000+/month

- Role: Manage engineering function, oversee multiple projects, strategic leadership

Focus: Business impact, people development, innovatio

Why Production Engineering is Your Best Path If You're Technical

Advantages:

- High earning potential: Engineering salaries grow faster and higher than supervisor roles

- Portable expertise: Your skills transfer between companies, sectors, even countries

- Intellectual engagement: Problem-solving is genuinely interesting work

- Impact visibility: See your improvements directly improve production

- Career flexibility: Can specialize or generalize, can advance in engineering or move to management

- Certification value: Industry certifications significantly boost salary and options

- Innovation opportunity: Leading-edge manufacturing involves AI, automation, Industry 4.0—exciting frontier

- International opportunity: Companies seek global manufacturing experts

When Production Engineering Might Not Be Ideal:

- If you prefer hands-on making over system design

- If you dislike sitting at desk for much of the day

- If you’re uncomfortable with complex technical software

- If you dislike continuous learning (requirements keep evolving)

If you prefer managing people over managing processes

Entry Requirements: How to Become a Production Engineer

Minimum Qualification:

- Bachelor’s degree in Engineering (Mechanical, Production, Industrial, Chemical preferred)

- Polytechnic diploma in relevant field (alternate path)

Preferred Background:

- Engineering internship in manufacturing

- Project experience (capstone project, industrial project)

- Understanding of manufacturing processes

- Basic CAD knowledge

Fast-Track Option:

- GET (Graduate Engineer Trainee) program: 6-12 month structured training then permanent role

- Companies actively recruit engineering freshers this way

Career-Switch Option:

- If you have technical background (non-engineering), can transition through short certifications

Requires strong fundamentals + willingness to learn fast

How to Excel as Production Engineer

Year 1 Priorities:

- Master CAD software (AutoCAD or SolidWorks)

- Understand your facility’s processes deeply

- Build relationships with operators (they know things engineers don’t)

- Complete Lean basic training

- Deliver at least one successful small improvement project

Year 2-3 Priorities:

- Develop specialization (one process area)

- Lead larger improvement projects

- Complete Lean Six Sigma Green Belt

- Mentor junior engineers or trainees

- Present findings to senior management

Year 4-6 Priorities:

- Become the go-to expert in your specialization

- Complete Lean Six Sigma Black Belt

- Lead cross-functional initiatives

- Mentor multiple junior engineers

- Contribute to company-wide strategy

- Consider MBA or advanced technical certification

The Bottom Line: Engineering is the Technical Career Accelerator

If you love understanding how things work, solving complex problems, and using technology to improve processes, production engineering is your path. The salary growth is excellent, the work is intellectually engaging, and the career is recession-proof and globally transferable. Engineering opens doors that supervisory roles don’t.

Your 5-year journey: Fresh graduate earning ₹25,000/month → Specialized engineer earning ₹75,000/month, with global opportunities and genuine impact on manufacturing excellence.