Quality Control Trainee—The Analytical Entry Path

Table of Contents

What Separates an Average Factory from an Excellent One? Quality Control.

Imagine two factories producing identical mobile phones. Factory A has loose quality control—70% of phones work perfectly, 20% have minor issues, 10% are defective. Factory B has rigorous quality control—99% perfect, 0.8% minor issues, 0.2% defective.

Which phone would you buy? Obviously Factory B.

This difference—between acceptable and excellent—is created by Quality Control teams. And if you’re analytical, detail-oriented, and enjoy problem-solving, QC is your manufacturing superpower.

Quality Control Trainee roles are your entry point into this critical function. Quality Control Engineers remain among the most in-demand roles in modern manufacturing.

What Quality Control Actually Means (Beyond "Checking Stuff")

Quality Control in manufacturing isn’t subjective judgment. It’s systematic, data-driven verification that products meet exact specifications.

Think of it like medical testing. A hospital doesn’t randomly decide whether blood test results are “good” or “bad.” They have exact standards: Red blood cell count should be between X and Y, cholesterol under Z, etc. Anything outside these ranges is flagged.

Manufacturing works identically.

A Product Specification Might State:

- “This component must be 50mm ± 0.1mm in length”

- “Surface must be free of visible defects larger than 1mm”

- “This fastener must withstand 500 Newtons of force”

- “This medication must contain 500mg ± 2mg of active ingredient”

QC’s job: Verify every product meets these standards.

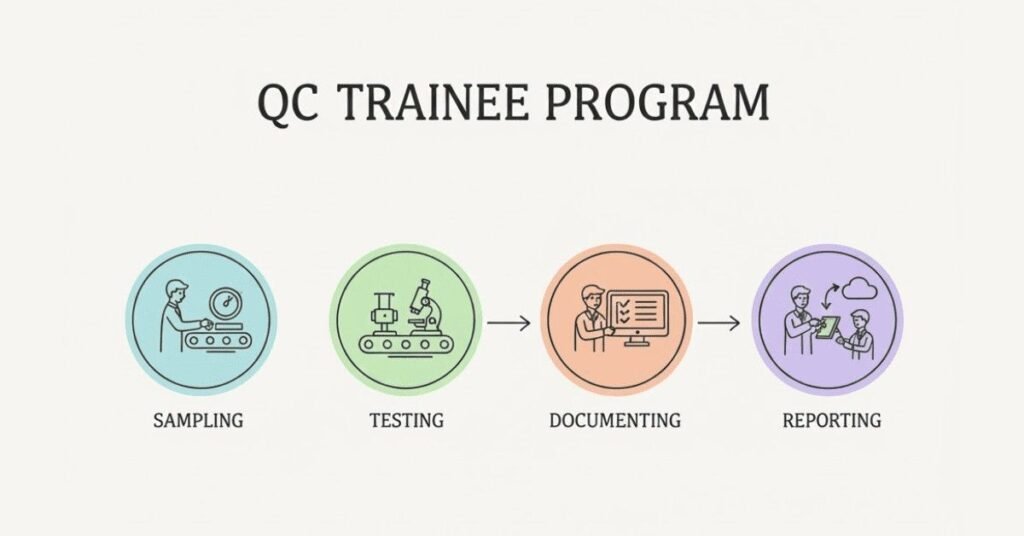

When you start as a QC Trainee, you learn:

- What specifications mean

- How to measure accurately

- How to identify when products don’t meet specifications

- How to document findings

How to flag issues before products reach customer

The Daily Work of a QC Trainee

Morning (7:30 AM – 10:30 AM):

Naveen, a QC trainee in a pharmaceutical manufacturing facility, arrives at 7:15 AM. His supervisor briefs him:

- Today’s production batch: 500 tablets of Medicine X

- Sampling plan: Inspect 50 tablets (10% of batch)

- Standards to verify: Weight, color, hardness, packaging accuracy

His workstation has:

- Digital balance (accurate to 0.01mg)

- Color comparison chart

- Hardness testing machine

- Packaging inspection checklist

- Computer system to record results

7:30 AM – 9:00 AM: Sample Collection Phase

Naveen collects samples from different parts of the production batch. Why different parts? Because defects aren’t always uniform across a batch. Defects at the beginning, middle, or end might differ due to equipment changes.

He carefully selects 50 tablets following a structured sampling plan to ensure randomness and representativeness.

9:00 AM – 10:30 AM: Testing Phase

He tests each tablet:

- Weight verification: Places tablet on digital balance. Records weight. Standard: 250mg ± 3mg. Result: Acceptable ✓

- Color check: Compares to reference color chart. Looks for discoloration, streaking, or uneven color. Result: Acceptable ✓

- Hardness test: Places tablet in hardness tester, applies pressure. Measures crushing strength. Standard: 80-120 Newtons. Result: 95N, Acceptable ✓

- Packaging inspection: Opens packaging. Checks label correctness, alignment, print quality. Ensures no damage to tablet inside. Result: Acceptable ✓

He documents every result in the QC system.

Mid-Morning (10:30 AM – 12:30 PM):

Result summary for 50 tablets tested:

- 48 tablets: 100% acceptable

- 2 tablets: Out of specification (weight below acceptable range)

Critical Decision Point:

The entire batch (500 tablets) failed inspection because 2 tablets out of 50 were below spec. This statistically represents potential issues with 2% of the batch. The batch is REJECTED.

This rejection prevents:

- 500 defective tablets reaching patients

- Company reputation damage

- Potential patient harm

- Regulatory penalties

- Costly recalls

One QC trainee’s careful inspection just prevented a massive problem. This is why QC matters.

Naveen documents the rejection, photographs the defective tablets, and reports to the production manager. Production stops. The cause is investigated. Usually: equipment calibration issue, raw material variation, or process parameter drift.

This investigation data is used to prevent future defects. QC isn’t just checking; it’s the feedback mechanism for continuous improvement.

Lunch (12:30 PM – 1:30 PM):

30 minutes lunch break.

Afternoon (1:30 PM – 5:00 PM):

Naveen continues with the next batch. This batch tests all acceptable. Released for packaging and distribution.

He also spends 30 minutes updating his QC notebook—documenting trends, challenges encountered, questions for his supervisor.

Total today: 100 tablets inspected across 2 batches. 1 batch rejected (preventing customer harm). Dozens of data points recorded. Key contribution to product quality and company reputation.

This is a typical QC Trainee day. Not glamorous. Highly important.

Skills You Need to Succeed as QC Trainee

Analytical Skills:

- Careful observation (spotting tiny defects)

- Pattern recognition (identifying trends)

- Logical thinking (understanding cause-and-effect)

- Data interpretation (making sense of numbers)

- Problem investigation (why did this fail?)

Technical Skills:

- Using precision measuring instruments (calipers, gauges, balances)

- Understanding technical specifications

- Basic statistical thinking (sampling, variation)

- Reading technical drawings

- Using QC software and systems

- Photography and documentation

Attention to Detail:

- This is the most critical skill

- You might inspect 100 items per day

- Missing even one defect is failure

- Consistency matters (same standards for item 1 and item 100)

- Cleanliness matters (dust affects measurements)

Communication Skills:

- Clearly reporting findings

- Documenting issues precisely

- Explaining results to production teams

- Asking clarifying questions

- Presenting data

Physical Capabilities:

- Ability to stand for extended periods (some QC stations require standing)

- Good eyesight (or corrected vision)

- Fine motor control (handling small components, using precision tools)

- No significant allergies (some sectors require controlled environments)

Soft Skills:

- Patience (inspections require sustained focus)

- Impartiality (treating all batches equally)

- Responsibility (your findings impact thousands)

- Learning ability (QC involves understanding complex specifications)

Reliability (consistency matters)

Salary Expectations for QC Path

Starting Salary:

₹10,000 – ₹20,000/month (QC Trainee)

With Performance Bonuses & Allowances:

- Base: ₹14,000

- Production bonuses: +₹1,500-3,000 (based on batches inspected, accuracy)

- Shift allowance: +₹1,000-2,000

- Attendance bonus: +₹500-1,000

- Actual take-home: ₹17,000-23,000/month

After 1 Year (QC Executive):

₹18,000 – ₹28,000/month

After 2 Years (Senior QC Executive):

₹25,000 – ₹35,000/month

After 3-4 Years (QA Supervisor):

₹32,000 – ₹45,000/month

After 5+ Years (Quality Manager):

₹45,000 – ₹70,000/month

Why QC Salary Grows Faster Than Production:

- Quality expertise is specialized (fewer people qualified)

- Quality managers are critical to company performance

- Quality certifications (Six Sigma, ISO auditor) command premium salary

- Progression to management is faster than production roles

Sector-Based Salary Variation:

Sector | QC Trainee Start | Quality Manager (5 yrs) |

Pharmaceuticals | ₹15,000-22,000 | ₹50,000-75,000 |

Automotive | ₹14,000-20,000 | ₹45,000-65,000 |

Electronics | ₹16,000-24,000 | ₹52,000-72,000 |

Food Processing | ₹12,000-18,000 | ₹38,000-55,000 |

Textiles | ₹11,000-16,000 | ₹30,000-45,000 |

Pharma QC pays best; textiles pays least. Choose your sector accordingly if salary is priority.

Career Progression: From QC Trainee to Quality Leadership

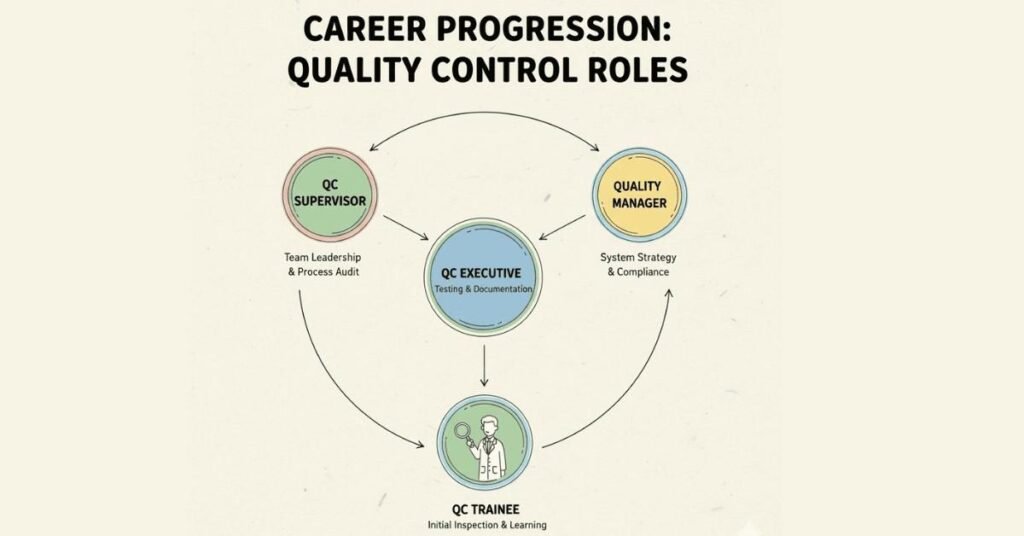

Year 1: QC Trainee

- Role: Learning inspection procedures, using basic tools

- Salary: ₹14,000-20,000/month

- Responsibilities: Inspecting products, documenting results

- Success Metric: Zero major defects missed, 100% documentation accuracy

Year 2: QC Executive

- Role: Independent inspector, quality standard owner

- Salary: ₹18,000-28,000/month

- Responsibilities: Inspecting batches, flagging non-conformances, training new trainees

- Advancement Path: Pursue basic quality certifications

Year 3: Senior QC Executive

- Role: Specialized in one quality area (dimensional, microbiology, packaging, etc.)

- Salary: ₹25,000-35,000/month

- Responsibilities: Complex testing, quality trend analysis, corrective actions

- Advancement Path: Pursue Six Sigma Green Belt certification

Year 4: QC Supervisor

- Role: Managing QC team (5-10 inspectors), planning sampling strategies

- Salary: ₹35,000-50,000/month

- Responsibilities: Team management, quality data analysis, process improvement

- Advancement Path: Pursue Six Sigma Black Belt if targeting management

Year 5: Quality Assurance Manager

- Role: Strategic quality planning, supplier management, compliance

- Salary: ₹50,000-70,000/month

- Responsibilities: Department leadership, regulatory compliance, system management

- Advancement Path: Senior management, potential plant-level responsibility

What This Means: A fresher starting at ₹14,000/month can reach ₹60,000+/month within 5 years by being analytical, reliable, and pursuing relevant certifications. The career path is clear and achievable.

Why QC Trainee is Your Best Entry If You're Analytical

Advantages of QC Career:

- Distinct expertise: Quality specialists are always in demand

- Faster management progression: Quality teams often reach supervisory roles quicker

- Specialization value: Deep expertise in one area makes you irreplaceable

- Certification path: Industry certifications (Six Sigma, Lean) boost both capability and salary

- Limited physical demand: Less standing than production roles

- Problem-solving daily: Not boring, constantly engaging mind

- Impact awareness: You directly prevent customer harm

When QC Might Not Be Ideal:

- If you dislike repetitive inspection (though each batch presents variations)

- If you need high social interaction (QC can be solitary)

- If you’re not detail-oriented (critical for success)

- If you get frustrated by slow, careful processes

- If you strongly prefer hands-on making vs. checking

Special Certifications That Boost QC Career

Unlike production roles, QC roles benefit significantly from certifications:

Six Sigma Green Belt:

- Duration: 40-60 hours training

- Cost: ₹15,000-30,000

- Benefit: Salary bump of ₹5,000-10,000/month, faster advancement

- ROI: Very high

ISO 9001 Internal Auditor:

- Duration: 20-30 hours training

- Cost: ₹8,000-15,000

- Benefit: Enables auditing role, salary bump ₹3,000-7,000/month

- ROI: High

Lean Specialist:

- Duration: 30-40 hours training

- Cost: ₹10,000-20,000

- Benefit: Positions for quality engineering roles, salary bump ₹4,000-8,000/month

- ROI: High

These certifications don’t just increase salary—they demonstrate commitment to quality excellence and open doors to advanced roles.

How to Land Your QC Trainee Role

Application Strategy:

- Identify companies with strong quality emphasis (pharma, automotive, electronics pay best)

- Highlight any analytical background (science subjects, data work, attention to detail)

- Research the company’s quality standards

- Show genuine interest in quality (not just any manufacturing job)

Interview Tips:

- Ask about quality standards and certifications

- Emphasize attention to detail with examples

- Show eagerness to learn quality methodologies

- Ask about career progression to management

- Request information about training programs

First Day Preparation:

- Arrive early

- Wear clean, professional casual clothes

- Bring notebook and pen (quality people document everything)

- Be ready to learn detailed specifications

- Show genuine interest